Textile recycling is the process of reusing or transforming textile waste into new products or materials. Textile recycling can help you save money, space, and resources, as well as reduce your environmental and social footprint.

But what exactly is textile recycling and how does it work? What are the benefits and challenges of textile recycling? How can you start textile recycling at home or in your community? What are the best practices and methods for textile recycling?

In this article, we will answer these questions and provide you with a comprehensive guide on textile recycling. We will explain everything you need to know about textile recycling, including:

- What is textile waste and why is it a problem?

- What are the benefits of textile recycling for the environment and the society?

- What are the methods of textile recycling and how do they work?

- How can you find and access textile recycling services or facilities?

- How can you sort and prepare your textile waste for recycling?

- How can you reduce your textile waste and consumption in the first place?

By the end of this article, you will have a clear understanding of what textile recycling is and why it matters for you as a consumer. You will also have some tips and resources on how to start textile recycling at home or in your community. Let’s get started!

What is Textile Waste and Why is it a Problem?

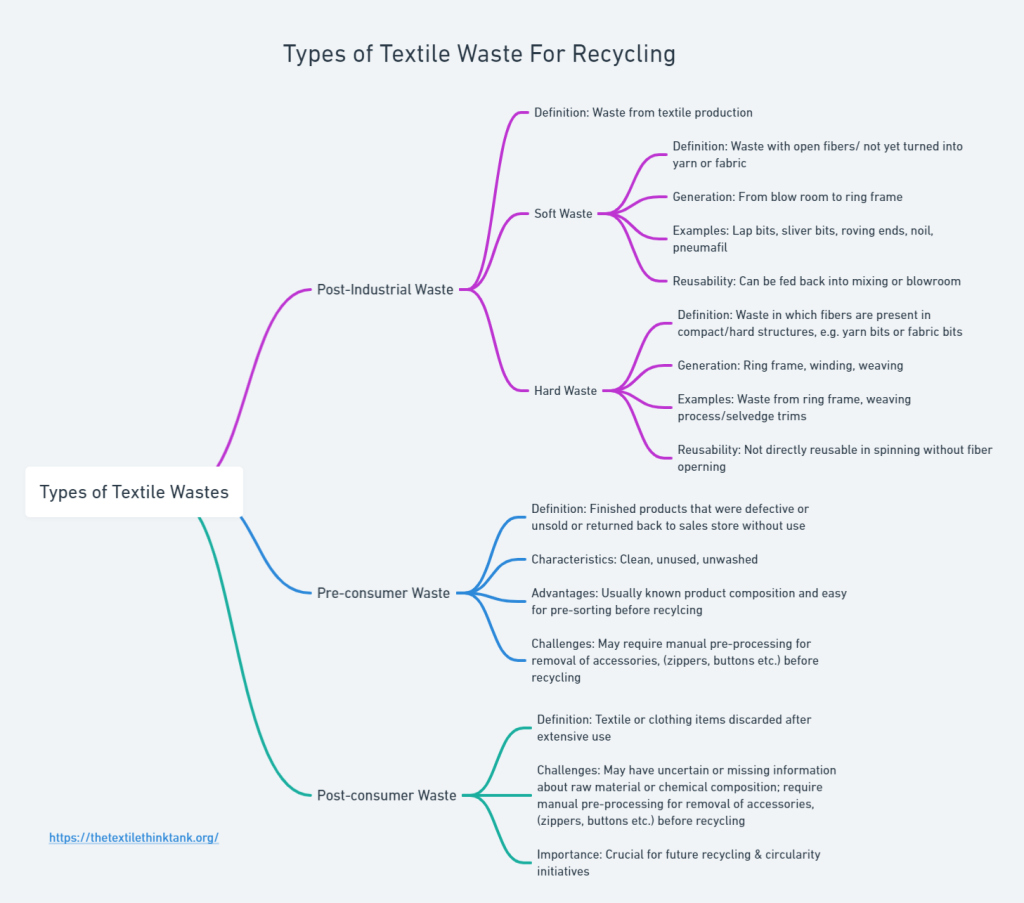

Textile waste is any discarded or unwanted textile material or product that is no longer in use or usable for its original purpose. It can come from various sources, given as follows:

Post-Industrial Waste

This is the waste generated by the textile industry during the production or manufacturing process of textile products.

- Soft waste is generated during processes like spinning, and can be reused or repurposed. Soft waste refers to waste in which fibers are in a relatively open structure and can be reused directly at an earlier feed stage. This type of waste is generated from the blow room to the ring frame in the spinning process. Examples of soft waste include lap bits, sliver bits, roving ends, pneumafil waste, and comber noil. These wastes can be collected from each department and can be fed back into the mixing or blowroom process in recommended proportions.

- On the other hand, hard waste refers to waste in which fibers are packed in a closed structure and need additional operations before they can be reused. This type of waste is produced in the ring frame, winding, weaving preparatory, and during weaving operations. Hard waste is not directly reusable in the spinning process. Examples of hard waste include waste generated waste from the ring frame, winding or waste during the weaving process.

It is essential to clarify that recycled material does not refer to waste generated during the regular short staple spinning process. For fibers to be considered “recycled material,” they must have been spun into yarn and then torn back into fibrous material, also known as “hard waste.”

Pre-consumer Waste

Pre-consumer waste refers to finished products, such as garments or household items, that were defective, not sold at retail or are returned unused. Unlike industrial waste, pre-consumer waste consists of items that have undergone the complete production process, such as dyeing/printing, finishing, and cut-and-sew operations. The advantage of pre-consumer waste is that it is typically clean, unused, and unwashed. Furthermore, the product categories are well known, which aids in pre-sorting the goods into different raw material groups, colors, and fabric types, a crucial step for subsequent processes.

However, pre-consumer waste also presents challenges. Similar to post-consumer waste, pre-consumer waste must undergo pre-processing before it can be recycled. This involves removing hardware such as buttons, zippers, and rivets, as well as distinctly different materials used in waistbands, collars, and cuffs. This process often has to be done manually, as automatic recognition, separation, and sorting of different hardware and other parts in a finished product is not yet feasible on an industrial scale.

Post-consumer Waste

Post-consumer textile waste refers to textiles that consumers discard after extensive use, such as worn-out garments, bedlinen, towels or other household textile items. These items have been worn, used, and washed multiple times, making them reach their lifespan.

A significant challenge is that these textiles often lack information about their raw materials, as labels become illegible or are removed due to wear and washing. Additionally, factors like fabric finishes, dyes, and coatings make the chemical composition uncertain, complicating the recycling process. This uncertainty hinders the pre-sorting phase and affects the quality of recycled materials produced.

Similar to pre-consumer waste from retail, hardware and other distinct materials must be manually removed before recycling. Although most industrialized nations lack standard collection processes for these textiles, ongoing initiatives suggest that post-consumer waste will be crucial in the future, especially if unsold textile quantities decrease and collection rates of used textiles increase.

Textile waste is a huge and growing problem in the world today. According to the Environmental Protection Agency (EPA), Americans generate more than 15 million metric tons of textile waste annually, which is about 47 kilograms (104 pounds) per person per year. Only 15% of that is collected for resale or recycling. The remaining 85% is directly discarded in landfills or incinerated.

Negative Impact of Textile Waste

Textile waste has a significant negative impact on the environment and the society, such as:

- Wasting natural resources: Textile production requires a lot of natural resources, such as water, land, energy, cotton, wool, silk, etc. According to the World Wildlife Fund (WWF), it takes about 2,700 liters of water to produce one cotton t-shirt, which is equivalent to the amount of water a person drinks in 2.5 years. Textile waste means that these resources are used for nothing and are lost forever.

- Emitting greenhouse gases: Textile production and disposal generate a lot of greenhouse gases, such as carbon dioxide, methane, nitrous oxide, etc. According to the United Nations Framework Convention on Climate Change (UNFCCC), the textile industry accounts for about 10% of global carbon emissions. Textile waste contributes to global warming and climate change by releasing more greenhouse gases into the atmosphere.

- Polluting the soil and water: Textile production and disposal involve the use of toxic chemicals and heavy metals, such as dyes, bleaches, solvents, pesticides, etc. These chemicals and metals can leach into the soil and water, contaminating them and harming the plants, animals, and humans that depend on them. Textile waste also creates microplastics, which are tiny pieces of plastic that can enter the food chain and cause health problems.

- Taking up landfill space: Textile waste occupies a lot of landfill space, which can cause environmental and health problems, such as soil and water contamination, methane emissions, fire hazards, etc. According to the EPA, about 11.3 million tons of textile waste were landfilled in the U.S. in 2018, which accounted for about 7.6% of the total municipal solid waste.

- Creating social and economic issues: Textile waste also creates social and economic issues for the people involved in the textile industry and the society at large. For example, textile waste can affect the livelihoods and incomes of the farmers, workers, and traders who depend on the textile sector. Textile waste can also increase the costs and burdens of waste management and disposal for the governments and communities.

What are the Benefits of Textile Recycling?

Textile recycling has many benefits for the environment and the society. By reusing or transforming textile waste into new products or materials, textile recycling can help to:

- Save natural resources: Textile production requires a lot of natural resources, such as water, land, energy, cotton, wool, silk, etc. According to the World Wildlife Fund (WWF), it takes about 2,700 liters of water to produce one cotton t-shirt, which is equivalent to the amount of water a person drinks in 2.5 years. Textile recycling can reduce the demand for natural resources by using existing materials instead of extracting new ones.

- Reduce greenhouse gas emissions: Textile production generates a lot of greenhouse gas emissions, such as carbon dioxide, methane, nitrous oxide, etc. According to the United Nations Framework Convention on Climate Change (UNFCCC), the textile industry accounts for about 10% of global carbon emissions. Textile recycling can reduce greenhouse gas emissions by avoiding or minimizing the use of fossil fuels and chemicals in textile production.

- Minimize waste generation: Textile production generates a lot of waste, such as fabric scraps, dyeing wastewater, packaging materials, etc. According to the Ellen MacArthur Foundation (EMF), about 87% of the total fiber input used for clothing production is landfilled or incinerated each year. Textile recycling can minimize waste generation by reusing or transforming waste materials into new products or materials.

- Conserve landfill space: Textile waste occupies a lot of landfill space, which can cause environmental and health problems, such as soil and water contamination, methane emissions, fire hazards, etc. According to the U.S. Environmental Protection Agency (EPA), about 11.3 million tons of textile waste were landfilled in the U.S. in 2018, which accounted for about 7.6% of the total municipal solid waste. Textile recycling can conserve landfill space by diverting textile waste from landfills and using it for other purposes.

- Create social and economic value: Textile recycling can create social and economic value by providing employment, income, and education opportunities for the people involved in the recycling process, such as collectors, sorters, recyclers, designers, etc. Textile recycling can also create value for the consumers by offering them more affordable, durable, and unique products that meet their needs and preferences.

What are the Methods of Textile Recycling?

Textile recycling can be done in different ways, depending on the type, quality, and quantity of the textile waste, as well as the desired outcome of the recycling process. Generally, there are two main methods of textile recycling: mechanical recycling and chemical recycling.

Mechanical Recycling

Mechanical recycling is the process of shredding or cutting textile waste into small pieces or fibers, and then spinning or felting them into new yarns or fabrics. It is the most common and widely used method of textile recycling, as it is relatively simple, cheap, and fast. However, mechanical recycling also has some limitations, such as:

- It can reduce the quality and strength of the recycled fibers, as they become shorter and weaker after shredding or cutting.

- It can generate a lot of dust and noise during the shredding or cutting process, which can cause health and safety issues for the workers and the environment.

Some examples of mechanical recycling are:

- Cotton recycling: Cotton recycling is the process of shredding or cutting cotton waste into small pieces or fibers, and then spinning them into new yarns or fabrics. Cotton recycling can use various sources of cotton waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Cotton recycling can produce various types of products, such as denim jeans, t-shirts, towels, etc.

- Wool recycling: Wool recycling is the process of shredding or cutting wool waste into small pieces or fibers, and then felting them into new fabrics. Wool recycling can use various sources of wool waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Wool recycling can produce various types of products, such as blankets, coats, sweaters, etc.

- Polyester recycling: Polyester recycling is the process of shredding or cutting polyester waste into small pieces or flakes, and then melting and extruding them into new fibers or pellets. Polyester recycling can use various sources of polyester waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Polyester recycling can produce various types of products, such as fleece jackets, sportswear, carpets, etc.

Chemical Recycling

Chemical recycling is the process of dissolving or breaking down textile waste into its basic components or monomers, and then re-polymerizing or re-combining them into new fibers or polymers. It is a more advanced and complex method of textile recycling, as it can overcome some of the limitations of mechanical recycling, such as:

- It can recycle mixed or heterogeneous textiles, such as cotton/polyester blends, while separating different fiber types from each other .

- It can maintain or improve the quality and strength of the recycled fibers, as they are regenerated from their original components or monomers.

- It can reduce the dust and noise generation during the recycling process, as it uses solvents or enzymes instead of shredding or cutting.

However, chemical recycling also has some challenges and barriers, such as:

- It requires more energy and resources than mechanical recycling, as it involves high temperature and pressure, complex machinery and equipment, sophisticated chemicals or enzymes, etc.

- It generates more waste and emissions than mechanical recycling, as it produces wastewater, solvent residues, by-products, etc., that need to be treated or disposed of properly.

- It faces more technical and regulatory hurdles than mechanical recycling, as it needs to ensure the safety and quality of the recycled fibers and products, comply with the environmental and health standards and regulations, etc.

Some examples of chemical recycling are:

- Viscose recycling: Viscose recycling is the process of dissolving cellulose-based textile waste such as cotton or rayon into a viscous solution called viscose, and then extruding it through a spinneret into new fibers called regenerated cellulose or rayon. Viscose recycling can use various sources of cellulose-based textile waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Viscose recycling can produce various types of products, such as dresses, shirts, scarves, etc.

- Polyester depolymerization: Polyester depolymerization is the process of breaking down polyester waste into its basic components or monomers, such as ethylene glycol and terephthalic acid, and then re-polymerizing them into new polyester fibers or pellets. Polyester depolymerization can use various sources of polyester waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Polyester depolymerization can produce various types of products, such as fleece jackets, sportswear, carpets, etc.

- Cotton recycling by enzymes: Cotton recycling by enzymes is the process of using enzymes to degrade cotton waste into glucose and other sugars, and then fermenting them into ethanol or other biofuels. Cotton recycling by enzymes can use various sources of cotton waste, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc. Cotton recycling by enzymes can produce various types of products, such as biofuels, bioplastics, biocomposites, etc.

How to Find and Access Textile Recycling Services or Facilities?

Textile recycling services or facilities are the places or organizations that collect, sort, process, and distribute textile waste for recycling. Textile recycling services or facilities can be public or private, for-profit or non-profit, local or global, depending on their scope and scale.

There are different ways to find and access textile recycling services or facilities, such as:

- Online search: You can use online search engines or directories to find textile recycling services or facilities near you or in your area. You can also use online platforms or apps that connect you with textile recycling services or facilities, such as SMART (Secondary Materials and Recycled Textiles Association), Earth911, RecycleNation, etc.

- Donation bins: You can use donation bins that are located in public places or in front of retail stores to drop off your textile waste for recycling. You can also use donation bins that are provided by charities or non-governmental organizations (NGOs) that collect textile waste for recycling, such as Goodwill, Salvation Army, Red Cross, etc.

- Curbside collection: You can use curbside collection programs that are offered by your local municipality or waste management company to pick up your textile waste for recycling. You can also use curbside collection programs that are offered by private companies or organizations that collect textile waste for recycling, such as Green Eileen, Wearable Collections, etc.

- Mail-in programs: You can use mail-in programs that are offered by online retailers or brands to send back your textile waste for recycling. You can also use mail-in programs that are offered by private companies or organizations that collect textile waste for recycling, such as For Days, ThredUp, The Renewal Workshop, etc.

- Take-back programs: You can use take-back programs that are offered by physical retailers or brands to bring back your textile waste for recycling. You can also use take-back programs that are offered by private companies or organizations that collect textile waste for recycling, such as H&M, Patagonia, Eileen Fisher, etc.

How to Sort and Prepare Your Textile Waste for Recycling?

Sorting and preparing your textile waste for recycling is an important step that can help to improve the efficiency and effectiveness of the recycling process. Sorting and preparing your textile waste for recycling can also help to reduce the contamination and degradation of the recycled materials.

There are different ways to sort and prepare your textile waste for recycling, such as:

- Checking the labels: You can check the labels of your textile products to identify the fiber type, composition, and origin of the materials. This can help you to separate different fiber types from each other, such as cotton, polyester, wool, etc. This can also help you to separate pure or homogeneous textiles from mixed or heterogeneous textiles, such as cotton/polyester blends, etc.

- Cleaning the textiles: You can clean your textile products to remove any dirt, stains, odors, or residues that may affect the quality or safety of the recycled materials. You can use mild detergents, water, and air drying to clean your textile products. You can also repair any damages or defects that may affect the functionality or appearance of the recycled products, such as holes, tears, buttons, zippers, etc.

- Folding or bagging the textiles: You can fold or bag your textile products to protect them from damage or contamination during transportation or storage. You can use reusable bags or containers to fold or bag your textile products. You can also label or tag your bags or containers to indicate the type, quantity, and quality of the textile products inside.

How to Reduce Your Textile Waste and Consumption in the First Place?

Textile recycling is a great way to deal with your textile waste and make a positive impact on the environment and the society. However, textile recycling is not the only or the best solution for textile waste management. The best solution is to reduce your textile waste and consumption in the first place.

There are different ways to reduce your textile waste and consumption in the first place, such as:

- Buying less: You can buy less textile products by avoiding impulse buying, following trends, or shopping for fun. You can buy less textile products by planning your purchases, setting a budget, making a list, and sticking to it. You can buy less textile products by choosing quality over quantity, durability over disposability, and timeless over trendy.

- Buying better: You can buy better textile products by choosing more sustainable materials, such as organic cotton, hemp, bamboo, recycled polyester, etc. You can buy better textile products by choosing more ethical brands, such as fair trade, certified organic, B Corp, etc. You can buy better textile products by choosing more circular models, such as rental, subscription, swap, etc.

- Buying secondhand: You can buy secondhand textile products by shopping at thrift stores, consignment shops, flea markets, garage sales, etc. You can buy secondhand textile products by using online platforms or apps that connect you with sellers or buyers of used textile products, such as Poshmark, ThredUp, Depop, etc. You can buy secondhand textile products by joining or organizing clothing swaps or exchanges with your friends, family, neighbors, or community.

- Caring more: You can care more for your textile products by washing them less frequently, using cold water and mild detergents, and air drying them. You can care more for your textile products by repairing when damaged or worn out, using patches, stitches, buttons, zippers, etc. You can care more for your textile products by storing them properly, using hangers, drawers, boxes, etc.

- Donating or recycling more: You can donate or recycle more of your textile products when you no longer need or want them. You can donate or recycle more of your textile products by using the methods and tips we discussed in the previous sections. You can donate or recycle more of your textile products by spreading the word and encouraging others to do the same.

How to Find and Buy Recycled Textile Products Online or in Stores?

Recycled textile products are becoming more popular and available in the market, as more consumers are becoming aware of the environmental and social benefits of textile recycling. However, finding and buying recycled textile products online or in stores can still be challenging for some consumers, as they may not know where to look for them, what to look for in them, or how to verify their authenticity and quality.

Here are some tips on how to find and buy recycled textile products online or in stores:

- Look for labels and certifications: One of the easiest ways to find and buy recycled textile products online or in stores is to look for labels and certifications that indicate the recycled content and origin of the products. Some of the common labels and certifications for recycled textile products are:

- Global Recycled Standard (GRS): The GRS is a voluntary standard that verifies the recycled content and origin of the products, as well as the environmental and social practices of the producers. The GRS requires that the products contain at least 20% recycled material by weight.

- Recycled Claim Standard (RCS): The RCS is a voluntary standard that verifies the recycled content and origin of the products. The RCS does not require a minimum percentage of recycled material by weight.

- Recycled Polyester Certification (R-PET): The R-PET is a voluntary certification that verifies the recycled content and origin of polyester products. The R-PET requires that the products contain at least 50% recycled polyester by weight.

- Recycled Cotton Certification (R-COT): The R-COT is a voluntary certification that verifies the recycled content and origin of cotton products. The R-COT requires that the products contain at least 50% recycled cotton by weight.

- Do some research: Another way to find and buy recycled textile products online or in stores is to do some research on the brands and products that offer recycled textiles. You can use various sources of information, such as websites, blogs, social media, magazines, etc., to learn more about the brands and products that offer recycled textiles. You can also look for reviews, ratings, testimonials, etc., from other consumers who have bought and used the recycled textile products. Some of the things to look for in your research are:

- The source and type of the recycled material: You should look for the source and type of the recycled material used in the products, such as post-consumer clothing, post-industrial scraps, pre-consumer offcuts, etc., as well as the type of fiber or fabric, such as cotton, polyester, wool, etc. This can help you to understand the environmental and social impact of the recycled material, as well as its quality and performance.

- The percentage and origin of the recycled content: You should look for the percentage and origin of the recycled content in the products, such as 50% recycled cotton from India, 100% recycled polyester from China, etc. This can help you to verify the authenticity and traceability of the recycled content, as well as its compliance with the labels and certifications.

- The process and technology of the recycling: You should look for the process and technology of the recycling used in the products, such as mechanical recycling, chemical recycling, enzymatic recycling, etc. This can help you to understand the efficiency and effectiveness of the recycling process, as well as its environmental and health implications.

- Ask questions: Another way to find and buy recycled textile products online or in stores is to ask questions to the sellers or producers of the products. You can use various channels of communication, such as email, phone, chat, etc., to ask questions to the sellers or producers of the products. Some of the questions to ask are:

- How do you collect and sort your textile waste?

- How do you recycle your textile waste into new products or materials?

- How do you ensure the quality and safety of your recycled products or materials?

- How do you measure and report your environmental and social impact of your recycling activities?

- How do you label and certify your recycled products or materials?

What are Some Examples of Brands and Products that Offer Recycled Textiles?

Recycled textile products are offered by various brands and products in different categories and segments of the market. Some of the examples of brands and products that offer recycled textiles are:

- Patagonia: Patagonia is a leading outdoor clothing and gear brand that offers various products made from recycled materials, such as jackets, vests, sweaters, shirts, pants, shorts, hats, bags, etc. Patagonia uses various sources and types of recycled materials, such as post-consumer plastic bottles, post-industrial cotton scraps, pre-consumer wool offcuts, etc. Patagonia also uses various methods and technologies of recycling, such as mechanical recycling, chemical recycling, etc. Patagonia labels and certifies its recycled products with the GRS and the RCS.

- H&M: H&M is a leading fast fashion brand that offers various products made from recycled materials, such as dresses, tops, skirts, jeans, jackets, coats, accessories, etc. H&M uses various sources and types of recycled materials, such as post-consumer clothing, post-industrial textile scraps, pre-consumer textile offcuts, etc. H&M also uses various methods and technologies of recycling, such as mechanical recycling, chemical recycling, etc. H&M labels and certifies its recycled products with the GRS and the RCS.

- Eileen Fisher: Eileen Fisher is a leading women’s clothing brand that offers various products made from recycled materials, such as sweaters, cardigans, tunics, pants, leggings, dresses, etc. Eileen Fisher uses various sources and types of recycled materials, such as post-consumer clothing, post-industrial textile scraps, pre-consumer textile offcuts, etc. Eileen Fisher also uses various methods and technologies of recycling, such as mechanical recycling, chemical recycling, etc. Eileen Fisher labels and certifies its recycled products with the GRS and the RCS.

- Adidas: Adidas is a leading sportswear and footwear brand that offers various products made from recycled materials, such as sneakers, t-shirts, hoodies, shorts, leggings, socks, etc. Adidas uses various sources and types of recycled materials, such as post-consumer plastic bottles, post-industrial textile scraps, pre-consumer textile offcuts, etc. Adidas also uses various methods and technologies of recycling, such as mechanical recycling, chemical recycling, etc. Adidas labels and certifies its recycled products with the GRS and the RCS.

- Reformation: Reformation is a leading sustainable fashion brand that offers various products made from recycled materials, such as dresses, tops, skirts, jeans, jackets, coats, accessories, etc. Reformation uses various sources and types of recycled materials, such as post-consumer clothing, post-industrial textile scraps, pre-consumer textile offcuts, etc. Reformation also uses various methods and technologies of recycling, such as mechanical recycling, chemical recycling, etc. Reformation labels and certifies its recycled products with the GRS and the RCS.

- These are just some of the examples of brands and products that offer recycled textiles. There are many more brands and products that offer recycled textiles in different categories and segments of the market. You can find and buy them online or in stores by following the tips we provided in the previous section.

Conclusion

Textile recycling is the process of reusing or transforming textile waste into new products or materials. Textile recycling can help to reduce the environmental and social impact of textile production and consumption, such as water and energy consumption, greenhouse gas emissions, landfill space, chemical pollution, etc.

Mechanical recycling is the process of shredding or cutting textile waste into small pieces or fibers, and then spinning or felting them into new yarns or fabrics. It is the most common and widely used method of textile recycling, as it is relatively simple, cheap, and fast. However, mechanical recycling also has some limitations, such as it can only recycle pure or homogeneous textiles, it can reduce the quality and strength of the recycled fibers, and it can generate a lot of dust and noise during the recycling process.

Chemical recycling is the process of dissolving or breaking down textile waste into its basic components or monomers, and then re-polymerizing or re-combining them into new fibers or polymers. It is a more advanced and complex method of textile recycling, as it can overcome some of the limitations of mechanical recycling, such as it can recycle mixed or heterogeneous textiles. It can maintain or improve the quality and strength of the recycled fibers, and it can reduce the dust and noise generation during the recycling process. However, chemical recycling also has some challenges and barriers, such as it requires more energy and resources than mechanical recycling, it generates more waste and emissions than mechanical recycling, and it faces more technical and regulatory hurdles than mechanical recycling.