What is recycled cotton?

– Recycled cotton is cotton that may be obtained from cotton products that have already been used and/or discarded, such as clothes, towels and bedding, etc.

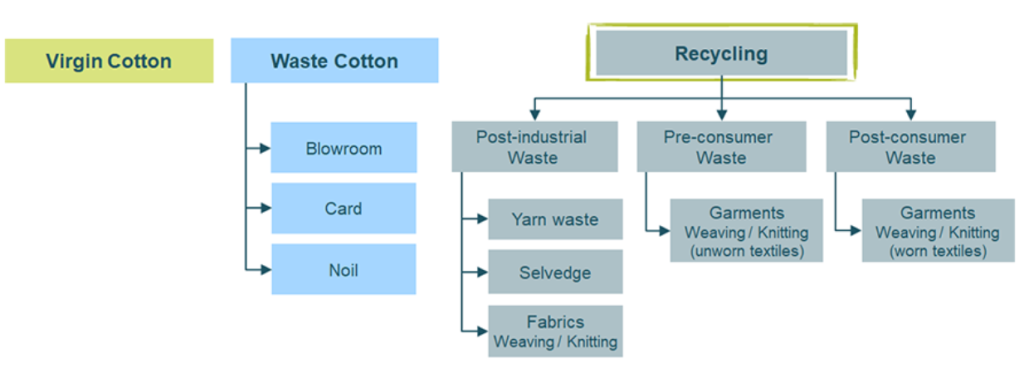

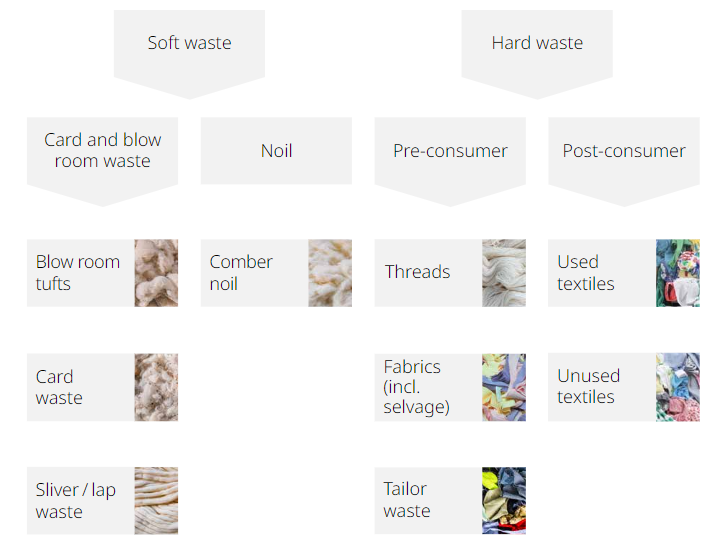

– Recycled cotton can be sourced from post-industrial waste, pre-consumer waste, or post-consumer waste.

– Post-industrial waste may include fiber or yarn waste from spinning, yarn waste from weaving or knitting, or fabric waste from garment manufacturing. Pre-consumer waste may include finished garments that could not be sold or used. These can be faulty goods, returns or overstock for example. Post-consumer waste may include garments that have been worn and are not further suitable for re-use.

– Recycled cotton is usually blended with other fibers, such as virgin cotton, polyester, or lyocell, to improve its quality and strength.

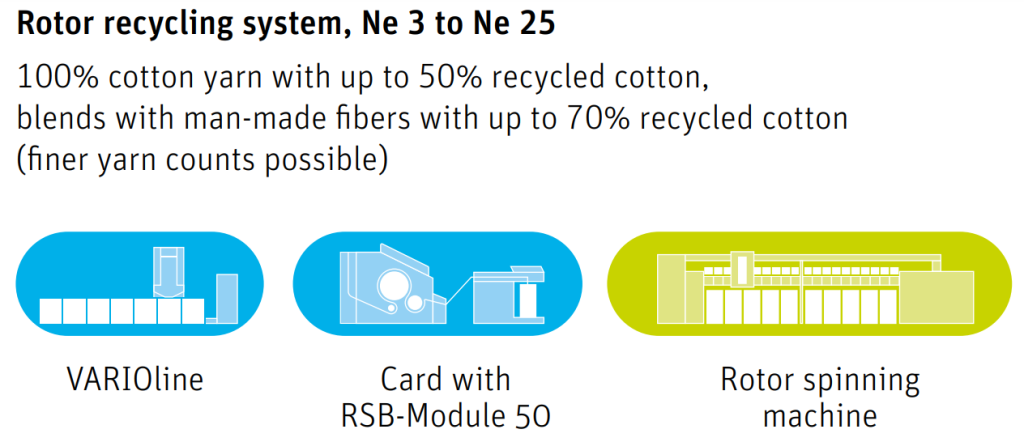

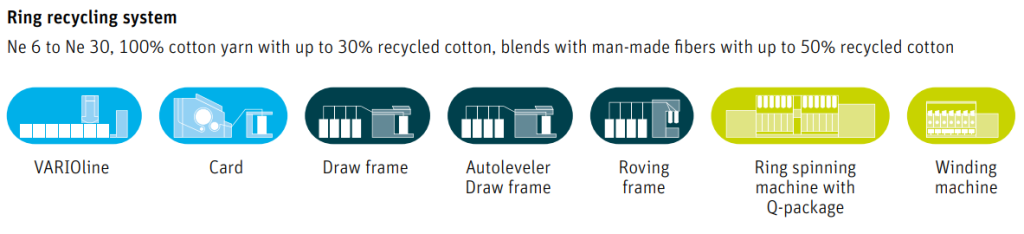

Images from Rieter & Recover

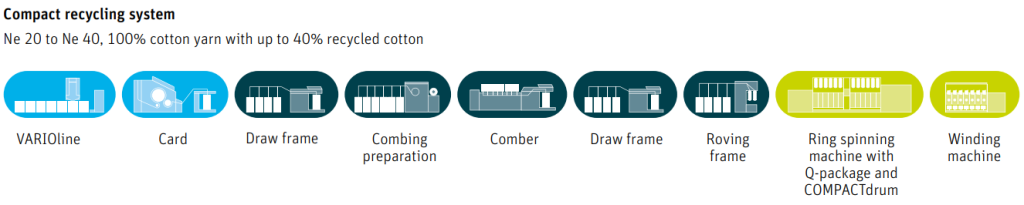

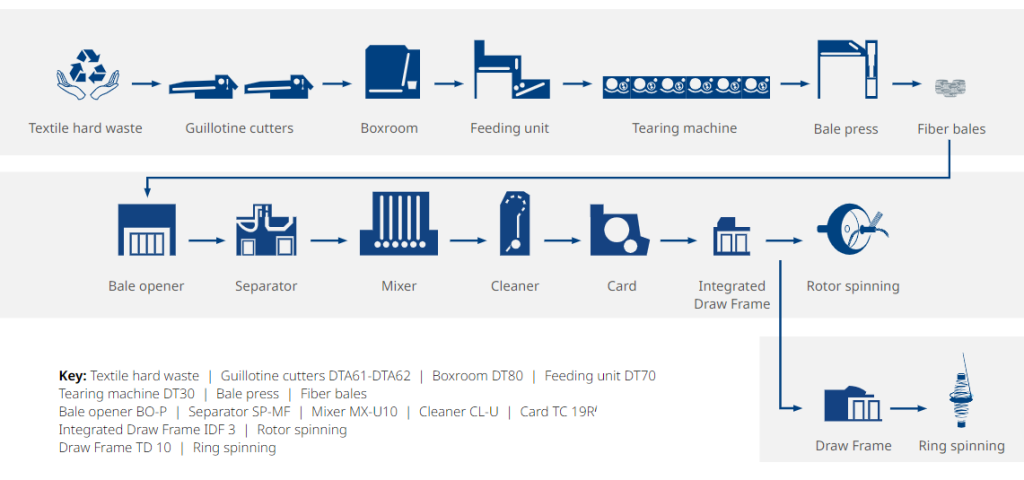

Image from truetzschler

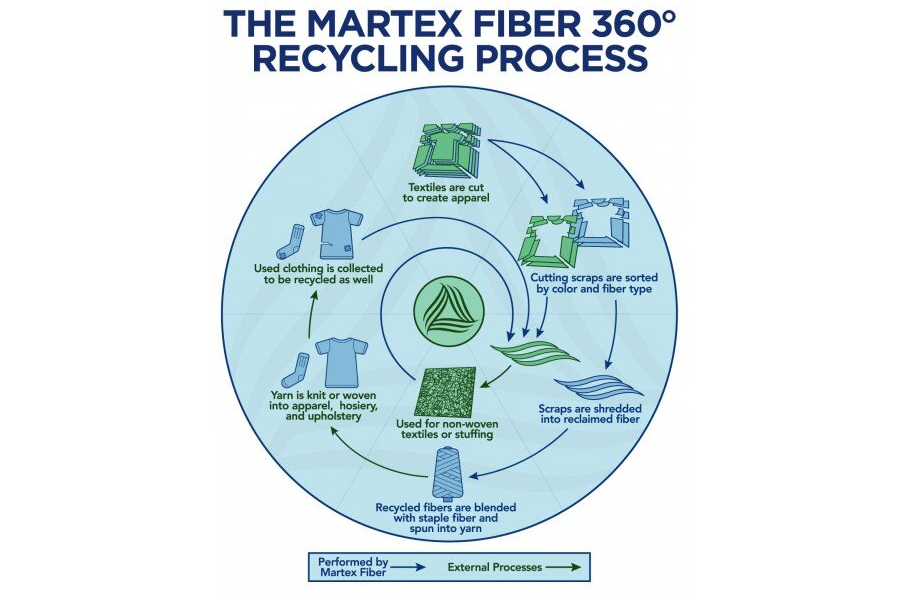

How is recycled cotton made?

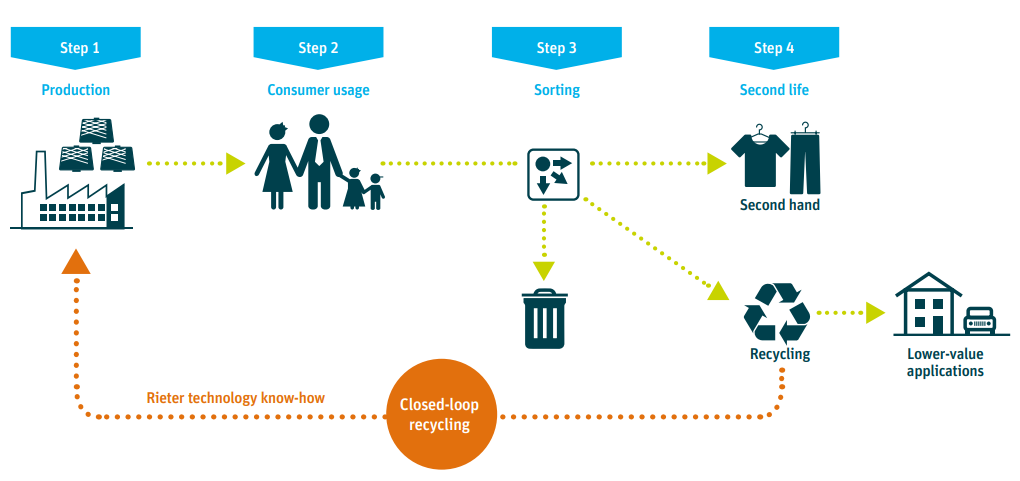

– Recycled cotton is made by sorting, shredding, and spinning the cotton waste into new yarns.

– The sorting process involves separating the cotton waste by color and fiber type. This reduces the need for dyeing and bleaching, which can save water and energy.

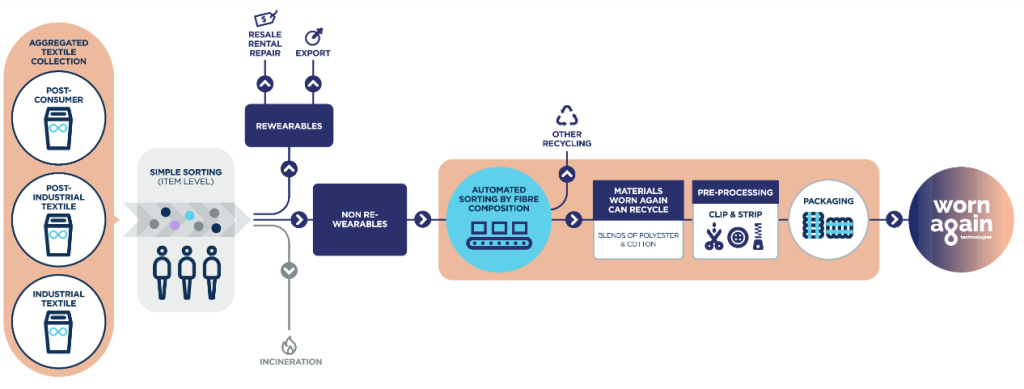

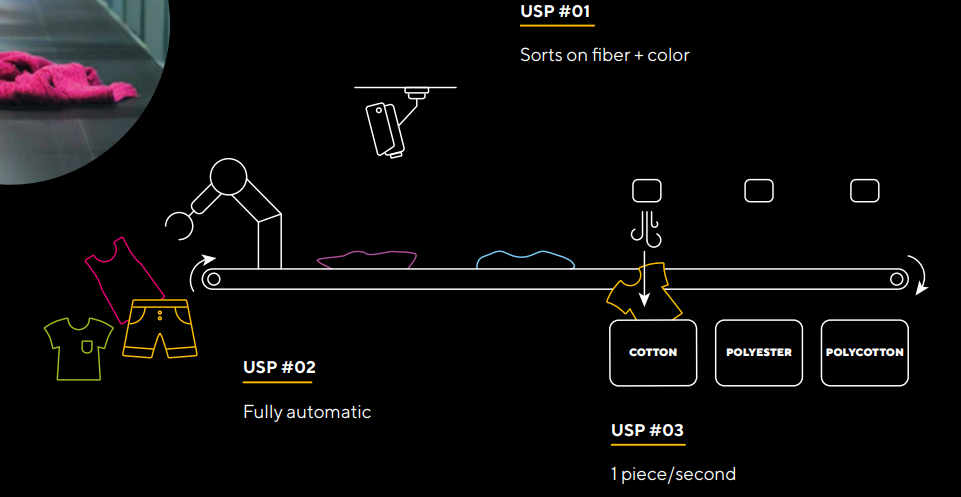

– Automated sorting technologies, such as Fibersort, have the potential to transform non-rewearable textiles that would otherwise be sent for downcycling, landfill, or incineration. Fibersort specifically utilizes Near Infrared (NIR) technology to categorize textiles into 42 different fractions based on their fiber composition. Fibersort can

also sort textiles based on color, using an RGB camera. This technology has undergone optimization, testing, and validation to make it ready for commercialization. Currently, Fibersort is capable of sorting approximately 900 kilograms of post-consumer textiles per hour.

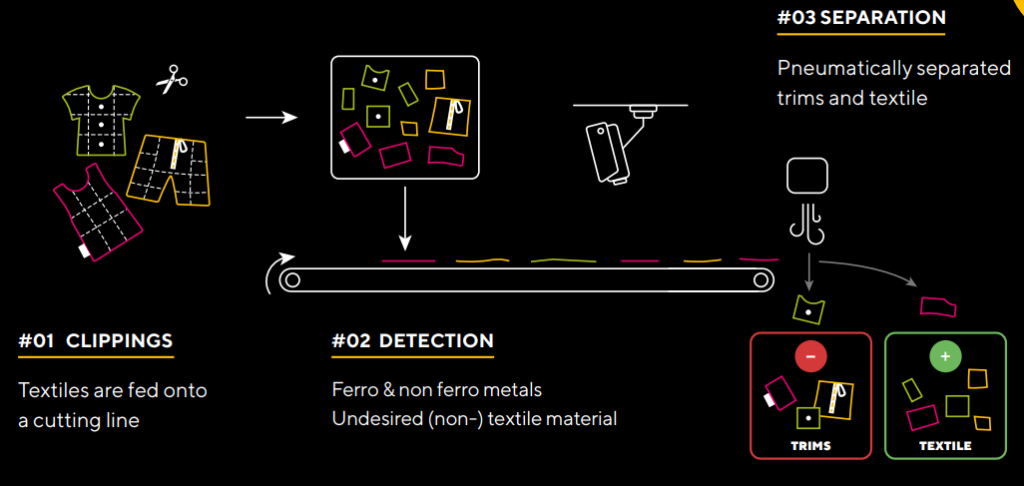

– Technologies like Trimclean can extract trims like zippers, buttons, and labels from fibersorted textile materials.

– Removing these undesired components increases the purity of the feedstock, creating a high-quality and reliable source for textile-to-textile recyclers. After the Fibersort process, the textiles are cut into small clippings measuring 20 to 100 mm on a cutting line. The clippings are then inspected by an optical camera system and a metal sensor in a detection area. The metal sensor detects both ferro and non-ferro metals, while the vision system identifies undesired non-textile materials such as labels and shoulder pads. Clippings with trims are pneumatically separated from the other clippings, resulting in two separate material flows. The untrimmed materials are used as feedstock to create new textile products.

– The shredding process involves tearing the cotton waste into small pieces using mechanical machines. This reduces the fiber length and strength, which can affect the quality of the yarns.

– The spinning process involves twisting the shredded fibers into new yarns using different techniques such as rotor, ring or compact system.

Images from Rieter

Recycling line from truetzschler

Why is recycled cotton more sustainable than conventional cotton?

– Recycled cotton reduces the environmental impact of cotton production by saving water, energy, land, and chemicals.

– According to various sources, recycled cotton uses 80% less water than conventional cotton, because it does not require irrigation or wet processing.

– Recycled cotton also uses less energy than conventional cotton, because it does not require fertilizers, pesticides, or high-temperature treatments.

– Recycled cotton saves land by avoiding the cultivation of new cotton crops, which can degrade soil quality and biodiversity.

– Recycled cotton reduces greenhouse gas emissions by avoiding synthetic chemicals and enhancing carbon sequestration in the soil.

– Recycled cotton also reduces textile waste by diverting cotton products from landfills and giving them a new life.

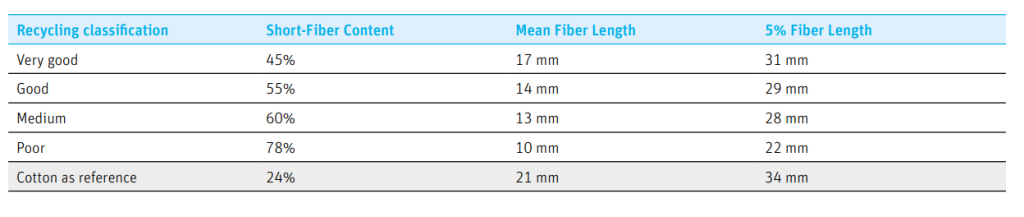

Typical parameters for mechanically recycled cotton fiber

| Feedstock | Output fiber length (mm) |

| Pre-consumer garment cutting waste; Pre-consumer yarn hard, woven selvedge waste | 6 to 21 |

| Pre-consumer denim/jeans waste | 6 to 18 |

| Pre-consumer yarn hard waste | 6 to 26* |

| Pre-consumer yarn hard waste [High quality fiber (length 29-40) in pre-consumer yarn] | Up to 26 |

*depending on input quality of pre-consumer material (https://textileexchange.org/)

How to choose recycled cotton products?

– Look for a certification label that verifies the recycled content of the cotton, such as the Global Recycled Standard (GRS), or the Recycled Claim Standard (RCS).

– Check the percentage of recycled cotton in the product, as some products may contain a low proportion of recycled cotton or other fibers. Ideally, look for products that have a high percentage of recycled cotton or are 100% recycled cotton.

– Consider the environmental and social impacts of other aspects of the product, such as dyeing, finishing, packaging, transportation, and labor practices. Look for products that use natural or low-impact dyes, biodegradable or recycled packaging, and ethical or fair trade standards.