The textile industry is facing many challenges and opportunities in the 21st century, such as changing consumer demands, increasing environmental regulations, rising labor costs, global competition, and technological disruption. To survive and thrive in this dynamic and complex environment, the textile industry needs to transform itself and embrace innovation. But what does innovation mean for the textile industry? How can the textile industry use data and technology to improve its processes, products, and performance? How can the textile industry create a textile factory of the future that is sustainable, efficient, and customer-centric? In this article, we will explore these questions and provide some insights and examples on how to build a textile factory of the future with data and innovation. We will cover the following topics:

- What is a textile factory of the future?

- Why do we need a textile factory of the future?

- How can we build a textile factory of the future?

- What are some examples of textile factories of the future?

What is a textile factory of the future?

A textile factory of the future is a smart and digitalized factory that uses data and technology to optimize its processes, products, and performance. A textile factory of the future leverages data-driven quality management, predictive analytics, artificial intelligence (AI), machine learning (ML), internet of things (IoT), robotics, automation, 3D printing, blockchain, cloud computing, and other emerging technologies to achieve the following goals:

- Reduce environmental impact: A textile factory of the future minimizes its water consumption, energy use, chemical use, waste generation, and carbon footprint by using innovative technologies such as dry dyeing, waterless washing, biodegradable materials, renewable energy sources, circular economy models, etc.

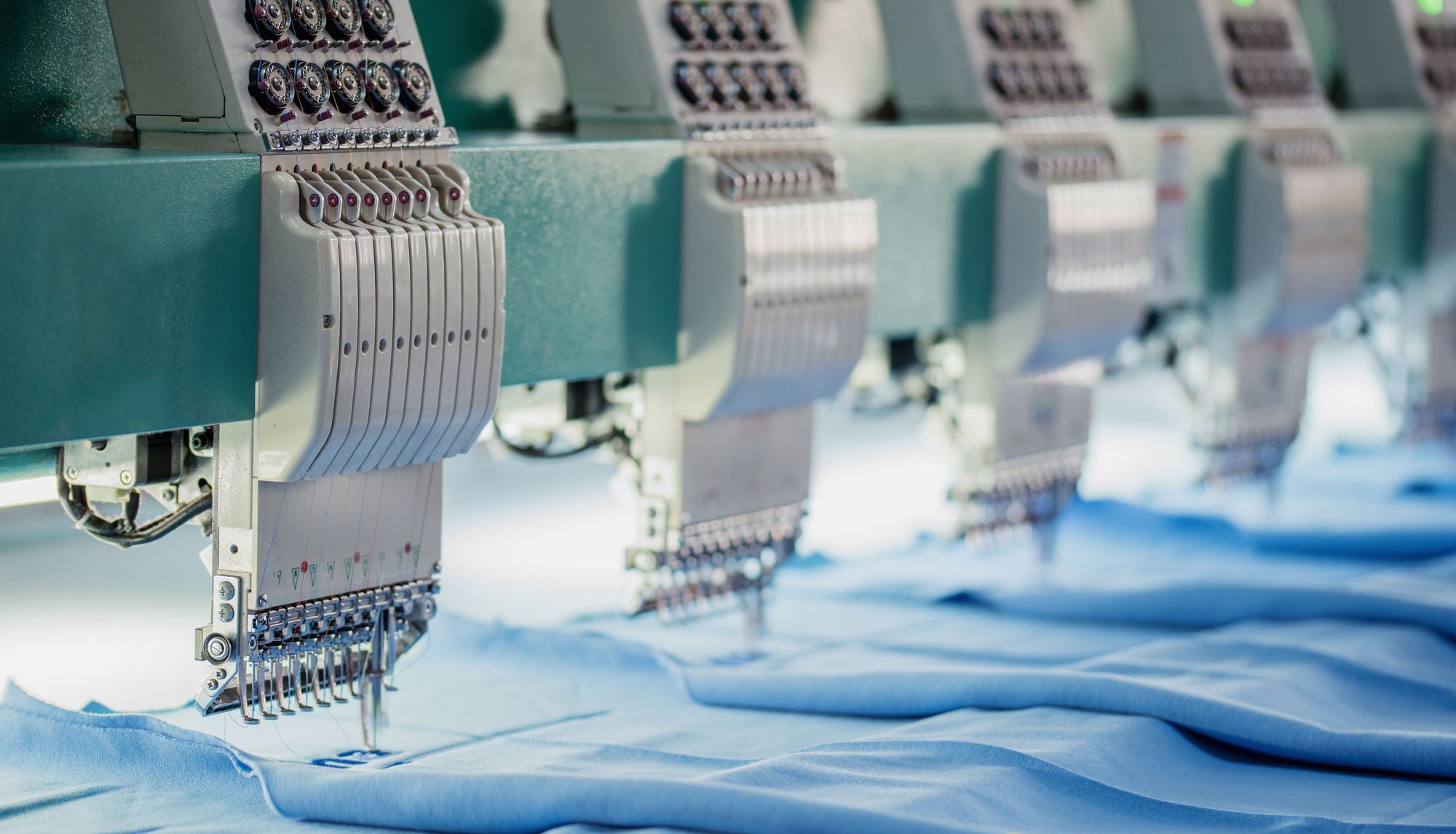

- Increase operational efficiency: A textile factory of the future maximizes its productivity, quality, flexibility, and agility by using data and technology to monitor, control, and optimize its processes, machines, and resources. A textile factory of the future also uses data and technology to automate and streamline its tasks, such as inspection, sorting, cutting, sewing, finishing, etc.

- Enhance customer satisfaction: A textile factory of the future meets and exceeds the expectations of its customers by using data and technology to customize and personalize its products and services. A textile factory of the future also uses data and technology to communicate and collaborate with its customers and stakeholders, such as suppliers, distributors, retailers, etc.

Why do we need a textile factory of the future?

A textile factory of the future is not only a desirable but also a necessary vision for the textile industry. A textile factory of the future can help the textile industry address some of the major challenges and opportunities that it faces in the 21st century, such as:

- Environmental sustainability: The textile industry is one of the biggest contributors to environmental degradation and climate change. According to the United Nations, the textile industry accounts for 10% of global carbon emissions, 20% of global wastewater, and 35% of microplastics in the oceans. The textile industry also consumes large amounts of water, energy, chemicals, and natural resources that are becoming scarce and expensive. A textile factory of the future can help the textile industry reduce its environmental impact and comply with the increasing environmental regulations and standards that are being imposed by governments and consumers.

- Customer demand: The textile industry is facing changing customer demand that is driven by factors such as globalization, digitalization, urbanization, social media, e-commerce, etc. Customers today are more informed, empowered, and demanding than ever before. They want products that are high-quality, affordable, convenient, fashionable, functional, and sustainable. They also want products that are customized and personalized to their preferences and needs. A textile factory of the future can help the textile industry meet and exceed customer demand by using data and technology to create products that are tailored to each customer’s specifications and expectations.

- Competitive advantage: The textile industry is facing intense global competition that is driven by factors such as innovation, diversification, specialization, and integration. The textile industry needs to constantly innovate and improve its products and processes to stay ahead of the curve and differentiate itself from the competitors. A textile factory of the future can help the textile industry gain a competitive advantage by using data and technology to create products and processes that are unique, superior, and efficient.

How can we build a textile factory of the future?

Building a textile factory of the future is not a simple or straightforward task. It requires a holistic and strategic approach that involves the following steps:

- Assess the current situation: The first step is to assess the current situation of your textile factory and identify its strengths, weaknesses, opportunities, and threats. You need to evaluate your current processes, products, performance, and customer satisfaction. You also need to benchmark your current situation against the best practices and standards in the industry and the market. You can use tools such as SWOT analysis, gap analysis, value stream mapping, etc. to conduct this assessment.

- Define the vision and goals: The second step is to define the vision and goals of your textile factory of the future. You need to articulate what you want to achieve and how you want to achieve it. You need to align your vision and goals with your business strategy and vision. You also need to communicate your vision and goals to your employees and stakeholders and get their buy-in and support. You can use tools such as SMART goals, mission statement, vision statement, etc. to define your vision and goals.

- Identify the solutions and technologies: The third step is to identify the solutions and technologies that can help you realize your vision and goals. You need to research and explore the various data-driven and innovative solutions and technologies that are available or emerging in the market. You need to evaluate their feasibility, suitability, compatibility, scalability, and affordability for your textile factory. You also need to consider their environmental, social, and economic impacts and benefits. You can use tools such as PESTEL analysis, SWOT analysis, cost-benefit analysis, etc. to identify the solutions and technologies.

- Implement the solutions and technologies: The fourth step is to implement the solutions and technologies that you have selected. You need to plan and execute the implementation process in a systematic and effective way. You need to allocate the resources, assign the roles and responsibilities, set the timelines and milestones, monitor the progress and performance, and manage the risks and issues. You also need to train and educate your employees and stakeholders on how to use the solutions and technologies. You can use tools such as project management software, Gantt charts, risk matrix, etc. to implement the solutions and technologies.

- Evaluate the results and outcomes: The fifth step is to evaluate the results and outcomes of your implementation process. You need to measure and analyze the impact and benefit of your solutions and technologies on your processes, products, performance, and customer satisfaction. You need to compare your results and outcomes with your vision and goals and identify the gaps and areas for improvement. You also need to collect and incorporate feedback from your employees, customers, and stakeholders on your solutions and technologies. You can use tools such as KPIs, dashboards, surveys, reviews, etc. to evaluate the results and outcomes.

What are some examples of textile factories of the future?

There are many examples of textile factories of the future that are already operating or being developed around the world. Here are some of them:

- Fashion for Good’s D(R)YE Factory of the Future: This is a consortium project that brings together several innovations in textile pre-treatment and coloration that aim to disrupt the current processing of textiles in the fashion supply chain. The project partners with adidas, Kering, PVH Corp., Arvind Limited, Welspun India, ColorZen, DyeCoo, and Archroma to create a factory that uses dry dyeing, waterless washing, biodegradable materials, and renewable energy sources to reduce water consumption, energy use, chemical use, waste generation, and carbon footprint.

- Good Business Lab’s Towards 2021: Innovating for the Future of Textiles & Garments Industry: This is a research and innovation project that focuses on improving the well-being of workers in the textile and garment industry. The project partners with Barco Uniforms, Levi Strauss & Co., Gap Inc., Shahi Exports, and others to use data and technology to monitor, evaluate, and improve the working conditions, health, safety, productivity, and income of workers. The project also uses data and technology to optimize the inspection process and criteria, reduce defects and errors, and enhance quality and efficiency.

- Textile Network’s Textile Factory of the Future: This is a vision and concept of a smart and digitalized factory that uses data and technology to optimize its processes, products, and performance. The concept involves using data-driven quality management, predictive analytics, artificial intelligence (AI), machine learning (ML), internet of things (IoT), robotics, automation, 3D printing, blockchain, cloud computing, and other emerging technologies to achieve the goals of reducing environmental impact, increasing operational efficiency, and enhancing customer satisfaction.

- Otto Grameen Textile Company’s Factory of the Future: This is a joint venture between Otto Group and Grameen Trust to establish a sustainable and social factory in Dhaka, Bangladesh. The factory aims to produce high-quality garments for the international market while providing decent work and income for the local workers. The factory also aims to use innovative technologies such as solar panels, rainwater harvesting, biogas plants, organic cotton, natural dyes, etc. to reduce its environmental impact and improve its social impact.

Conclusion

The textile industry is undergoing a transformation that is driven by data and innovation. The textile industry needs to build a textile factory of the future that is smart and digitalized, sustainable and efficient, and customer-centric and competitive. The textile industry can achieve this by using data and technology to optimize its processes, products, and performance, and by following a holistic and strategic approach that involves assessing the current situation, defining the vision and goals, identifying the solutions and technologies, implementing the solutions and technologies, and evaluating the results and outcomes.

The textile industry can also learn from the examples of textile factories of the future that are already operating or being developed around the world. These examples show how data and innovation can help the textile industry address some of the major challenges and opportunities that it faces in the 21st century, such as environmental sustainability, customer demand, and competitive advantage.

Are you ready to build your own textile factory of the future? If yes, then you need to start today. You need to embrace data and innovation as your key drivers for change and improvement. You need to invest in data and technology that can help you achieve your vision and goals. You need to collaborate with your employees, customers, and stakeholders to create a textile factory of the future that is beneficial for everyone.

If you want to learn more about how to build a textile factory of the future with data and innovation, you can contact us for consultation on how we can help you with your data-driven quality management needs.

Don’t wait any longer. Start building your textile factory of the future today!