The garment industry is on the brink of a revolution, led by the rise of microfactories. These smaller, modular manufacturing units utilize advanced technologies. These technologies include AI to optimize operations, offering a compelling alternative to traditional large-scale factories.

Inefficiencies in Traditional Garment Manufacturing

Traditional garment factories often face challenges such as high energy consumption, excessive waste, and rigid production lines. These cannot quickly adapt to changing fashion trends or consumer demands. These inefficiencies lead to higher costs and environmental impacts. This makes it difficult for these factories to meet the increasing demand for sustainable and customizable clothing options.

Growing Demand for Sustainable and Agile Manufacturing

As consumers become more environmentally conscious, they demand garments that are not only stylish and affordable but also made sustainably. Traditional factories struggle to keep up with these demands due to their large scale and inflexible operations. This gap in the market presents a significant problem for the industry, as failure to adapt could result in lost market share to more agile and sustainable competitors.

The Solution: Embracing Microfactories in Garment Production

Microfactories offer a sustainable and efficient alternative to traditional garment manufacturing. By integrating state-of-the-art technologies such as AI, automation, and the Industrial Internet of Things (IIoT), these facilities can dramatically improve cost, efficiency, and energy usage.

Cost-Effectiveness and Speed

Microfactories require significantly lower investment compared to traditional factories. Their modular nature allows for rapid changes and updates, reducing downtime and keeping production costs under control. For the garment industry, this means being able to respond quickly to fashion trends and consumer demands without excessive expenditure.

Customization and Flexibility

The use of AI and automation in microfactories enables highly personalized production runs. Garment manufacturers can easily adjust their operations to produce a wide range of styles and sizes, meeting consumer demands for customization without the need for large inventories.

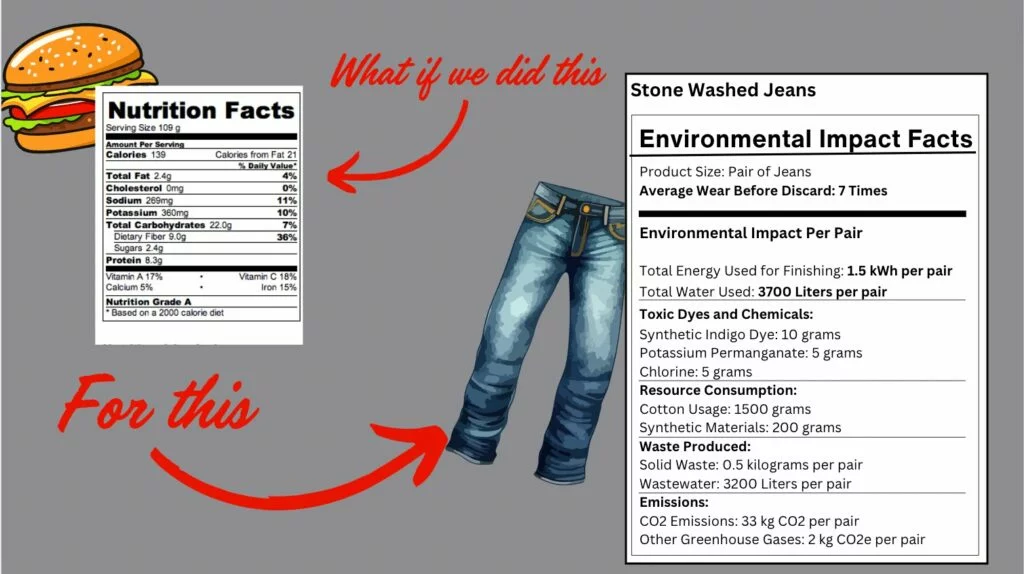

Sustainability and Reduced Environmental Impact

Microfactories are designed to be more energy-efficient and use fewer resources than traditional factories. They often consume up to 90% less water and 80% less energy. This not only helps reduce the environmental footprint of garment production but also aligns with global sustainability goals and consumer expectations.

Enhanced Maintenance and Scalability

The standardized modular setup of microfactories simplifies maintenance and enhances scalability. Components can be easily replaced or upgraded, which is more cost-effective and less time-consuming than overhauling large traditional factories. This modularity also supports the rapid scaling of operations to different regions, further reducing the carbon footprint associated with shipping and logistics.

Case Study: Arrival’s Microfactory

A pertinent example of microfactory success comes from the automotive industry. UK-based electric vehicle manufacturer Arrival has implemented decentralized microfactories that are highly automated and adaptable. These facilities have been constructed at a fraction of the cost of traditional factories and are designed to meet specific local demands quickly and efficiently.

Conclusion: Microfactories as the Blueprint for Future Garment Factories

Microfactories represent the next step in the evolution of garment manufacturing. With their ability to reduce costs, enhance flexibility, and minimize environmental impact, they are well-suited to meet the challenges of modern garment production. As the industry continues to evolve, adopting microfactory technology will be crucial for manufacturers looking to stay competitive in a fast-changing market.

Manufacturers must consider transitioning to microfactory models to meet the demands of a dynamic global market and drive forward the sustainable transformation of the garment industry. With the right tools, strategies, and technologies, microfactories can lead the way in creating a more sustainable, efficient, and consumer-responsive fashion world.