IDF+1 VORTEX SPINNING

Complexity and Cost of Traditional Spinning Processes

In traditional airjet spinning, manufacturers need to employ multiple draw frames to ensure optimal yarn quality. This complexity requires more space, equipment, and energy, resulting in higher production costs. Additionally, long preparation processes can slow down production speed and affect efficiency.

Difficulties of Streamlining Spinning

Reducing the number of draw frames is a challenge. Without careful preparation, reducing equipment risks compromising yarn quality, leading to inconsistencies in the final fabric. Manufacturers are often reluctant to invest in new methods without assurance that product quality will remain intact.

Trützschler’s IDF+1 VORTEX Simplifies Spinning Preparation

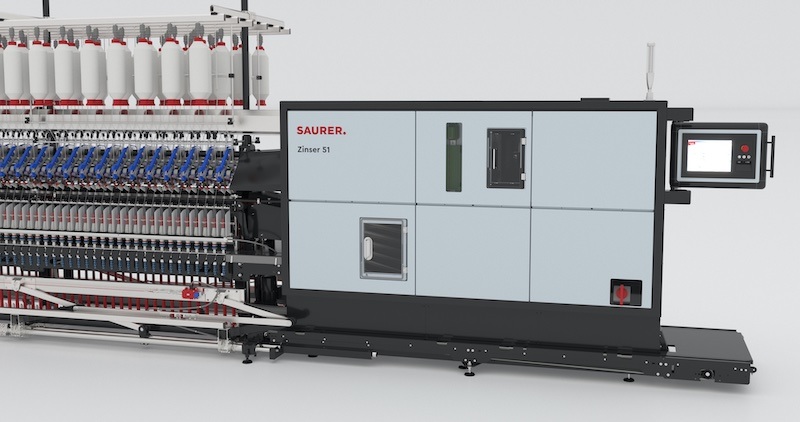

Trützschler’s Integrated Draw Frame (IDF) technology revolutionizes spinning by significantly reducing the number of required draw frames. Their latest development, the IDF 3, simplifies airjet spinning while maintaining high yarn quality.

How IDF VORTEX Works:

- Shortens the Preparation Process: For airjet spinning, traditional spinning requires one card and three draw frames. With IDF+1 VORTEX, manufacturers only need one card and one finisher, eliminating two draw frames entirely.

- Saves Space and Energy: Fewer machines mean reduced space and energy consumption, directly cutting operational costs.

- Reliable Yarn Quality: Initial trials confirm that synthetics and yarns up to Ne 40 maintain consistent quality compared to traditional processes. Fabrics made with the IDF+1 process show no significant quality differences.

Research and Development:

Trützschler’s research started in 2015 and involved numerous trials across different global markets. The system debuted at ITMA Asia 2018 and ITMA 2019, leading to increased demand, particularly in India. Their continued innovation aims to extend IDF’s capabilities to finer yarn counts and alternative raw materials, including Lyocell and various blends.

Industry Collaboration:

Murata, a key Trützschler partner, has applied the IDF+1 system to over 200 spinning machines:

- Improved Efficiency: Yarn cut levels are lower compared to the conventional three-passage system.

- Quality Consistency: Any differences between the IDF+1 and traditional three-passage methods are minimal and not noticeable in the final fabric.

Mr. Masazumi Shigeyama, VORTEX Product Manager, lauds Trützschler’s system as perfect for their sustainable and smart VORTEX factory.

Conclusion: IDF VORTEX Unlocks New Economic Potential

Trützschler’s IDF VORTEX SPINNING dramatically reduces spinning preparation costs while maintaining fabric quality, making it a game-changer for textile manufacturers. The simplified process offers economic benefits through reduced energy consumption, space savings, and operational efficiency, setting a new standard in the textile industry. With further R&D on finer yarn counts and new material blends, the IDF system is poised to unlock even greater economic advantages for manufacturers worldwide.