PFAS-Free Water-Repellent

Harmful PFAS Chemicals in Water-Repellent Textiles

Textiles designed to repel water, such as rain jackets and swimwear, have traditionally relied on PFAS (Per- and polyfluoroalkyl substances) for water-repellent properties. While effective, PFAS chemicals have significant downsides: they accumulate in the environment and are hazardous to human health. Manufacturers have been urgently seeking safer alternatives to these fluorine-based chemicals.

The Risks of Conventional PFAS Coatings

Despite their effectiveness, PFAS chemicals are non-biodegradable, accumulating in water systems and food chains, and exposing humans to long-term health risks. Furthermore, their performance in stretchy fabrics diminishes significantly after repeated washes, reducing the longevity and reliability of garments.

Empa’s Innovative PFAS-Free Plasma Coating

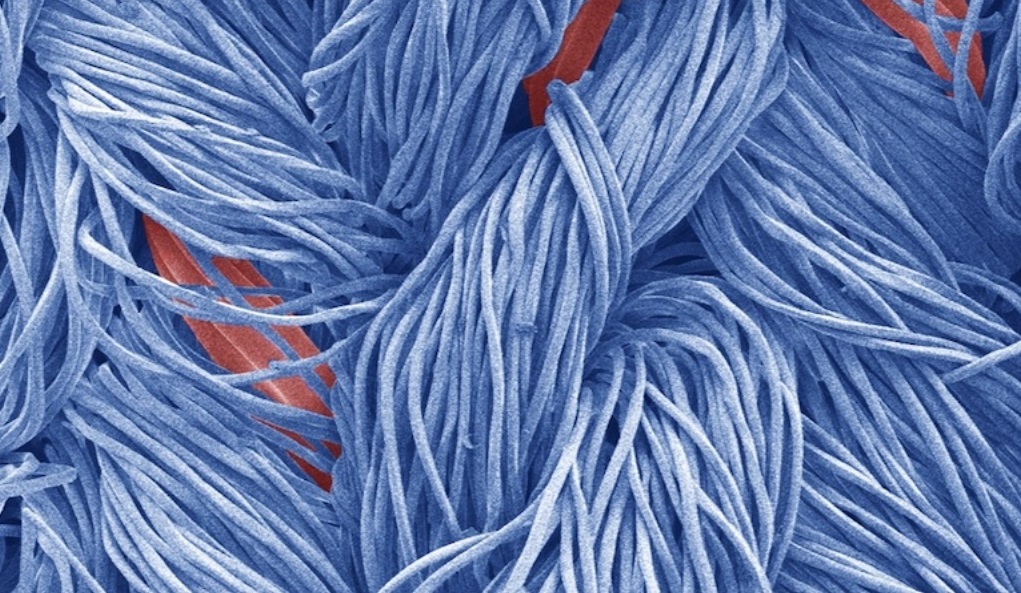

Empa, the Swiss research institute, has developed a cutting-edge plasma coating technology that uses highly cross-linked siloxanes to create silicone-like layers on textile fibers. The result is an environmentally friendly, water-repellent coating that is just 30 nanometers thick but provides superior performance. Here’s how it works:

Precision Plasma Coating

- Plasma Clouds: Siloxanes are atomized into a reactive gas and form a plasma cloud. This plasma evenly coats each textile fiber with nanometer precision, ensuring seamless hydrophobic protection.

- Enhanced Fiber Properties: Unlike traditional coatings, the siloxane layer uniformly covers the fiber, including intricate curves and twists, preventing water penetration and ensuring rapid drying.

Performance Advantages

- Better Than PFAS: Initial tests show these new fibers perform better than PFAS-coated fabrics. They absorb less water, dry faster, and remain water-repellent even after multiple washes.

- Resilient Stretch Fabrics: The new coating adheres firmly to elastic fibers, which have traditionally been challenging to coat effectively. Stretch fabrics now maintain their water-repellent properties over time.

Great Interest from Industry

Swiss textile companies Lothos KLG, beag Bäumlin & Ernst AG, and AG Cilander are already partnering with Empa to integrate this new technology into their products. They see the potential for both environmental and economic benefits:

- Sustainable Impact: The coating is free from harmful chemicals and provides an effective water-repellent finish that lasts longer than PFAS.

- Economic Potential: Companies recognize the opportunity to offer consumers high-quality, eco-friendly products with better durability.

Conclusion: Plasma Coating Leading the Way for Sustainable Textiles

Empa’s plasma coating technology offers a transformative alternative to PFAS-based coatings. With its environmentally friendly process, precision application, and long-lasting performance, it is setting a new standard for sustainable water-repellent textiles. This breakthrough allows manufacturers to meet growing consumer demand for eco-friendly products while ensuring quality and durability remain uncompromised.