Water-Free Dyeing and Finishing

Environmental Impact of Traditional Textile Processes

The textile industry is responsible for significant water pollution and carbon emissions. It has long relied on antiquated processes that consume vast amounts of water and chemicals. The dyeing and finishing phases of textile manufacturing alone contribute to 20% of global water pollution.

Urgent Need for Sustainable Solutions

Traditional methods of textile dyeing and finishing not only require excessive water but also discharge pollutants that harm ecosystems and human health. This unsustainable practice is increasingly at odds with global efforts to reduce environmental footprints and foster sustainability in industrial operations.

Ausora™ by Xefco – A Clean and Efficient Alternative

Innovative Technology

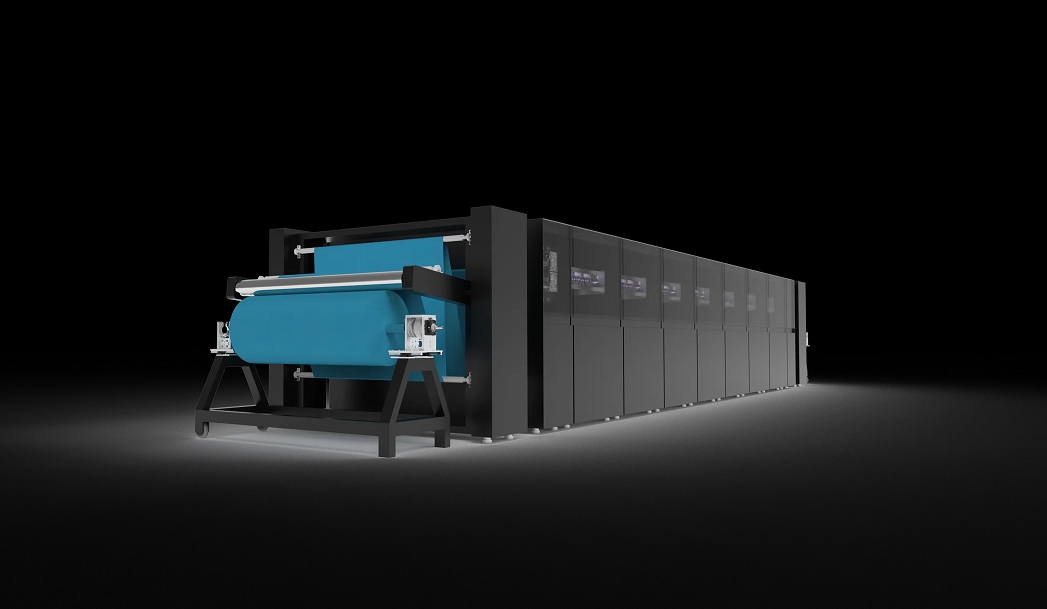

Ausora™ employs a groundbreaking plasma coating process that completely eliminates the use of water in dyeing and finishing textiles. This technology uses atmospheric pressure plasma, powered by electricity and argon gas. This is used to apply ultra-thin, durable coatings to both natural and synthetic fabrics.

Environmental Benefits

- Zero Water Waste: Ausora™’s process does not use or discharge any water, tackling one of the textile industry’s most significant environmental issues head-on.

- Reduced Chemical and Energy Use: It consumes 97% less chemistry and 90% less energy compared to traditional methods, enhancing its sustainability profile.

- No Polluted Water Discharge: The technology ensures there is no pollution from dyeing and finishing processes.

Functional Advantages

- Durable Water Repellency and More: Ausora™ not only makes textiles water-repellent but can also add properties like moisture-wicking, fire retardancy, self-cleaning, and anti-odor.

- Vibrant and Durable Colors: The plasma dyeing technique offers a broad color gamut with excellent colorfastness, crucial for maintaining the aesthetic appeal of fabrics over time.

Industry Impact

Xefco collaborates with global brands and manufacturers, integrating Ausora™ into mainstream production lines to replace older, less efficient systems. This collaboration not only benefits the environment but also provides manufacturers with a competitive edge in the market by aligning with consumer demand for sustainable products.

Conclusion: Shaping a Sustainable Future

Xefco’s Ausora™ represents a significant leap forward in textile manufacturing, aligning with global sustainability goals and offering a viable, environmentally friendly alternative to traditional practices. By adopting Ausora™, the textile industry can dramatically reduce its environmental impact while achieving better efficiency and product quality. This innovative approach is a testament to how technology can transform industries and promote a more sustainable future.