Fabric defects are a major challenge for textile manufacturers, as they can lead to waste, rework, and customer dissatisfaction. But what if there was a way to detect and prevent fabric defects in real time, using artificial intelligence? In this article, we will introduce you to an online knitted Fabric Defect Detection (FDD) system from Pailung, that detects fabric defects inside the knitting machine, and offers many other benefits for textile production.

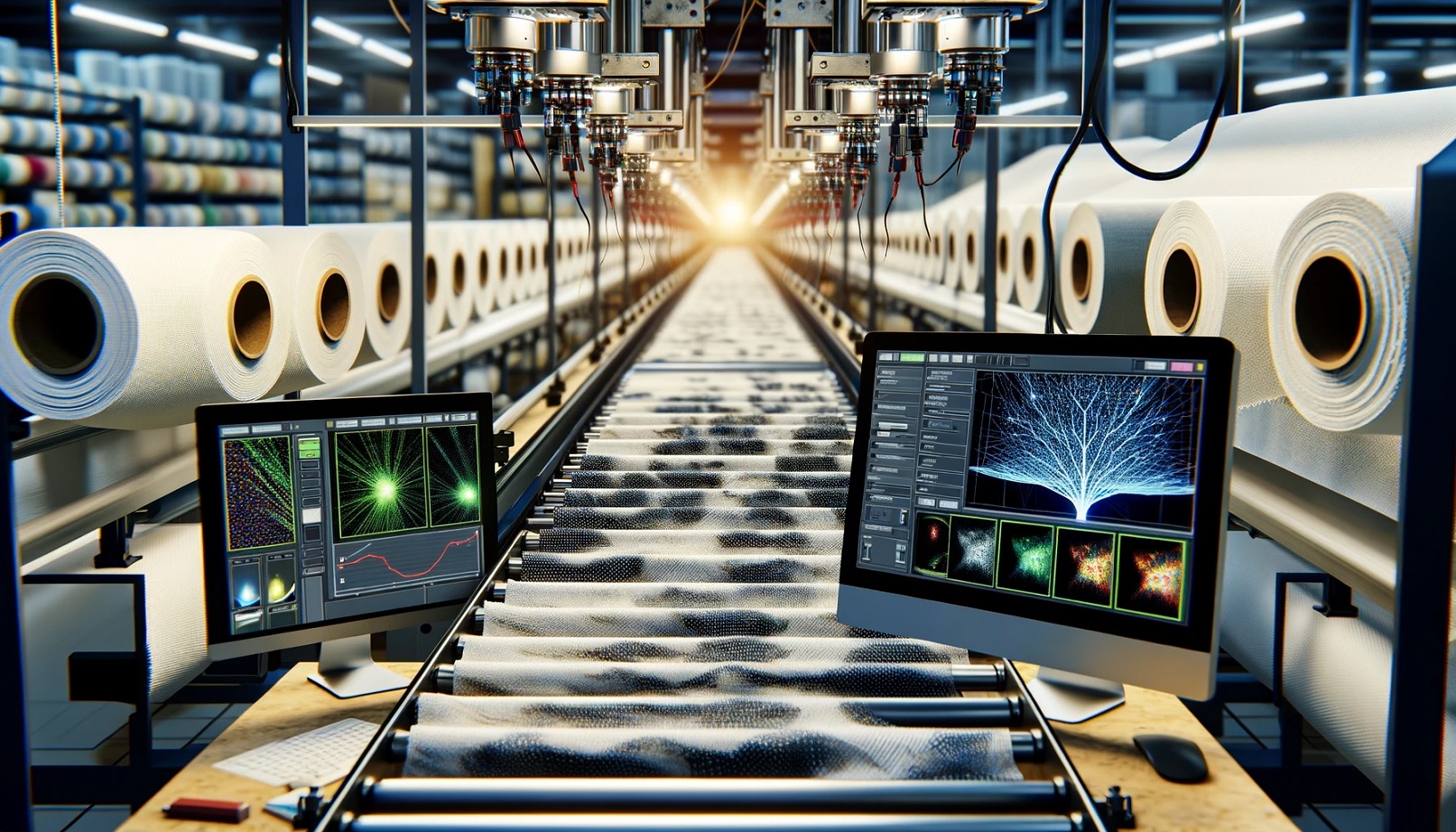

AI Fabric Inspection From Pailung is a software suite that uses computer vision to detect fabric defects inside the knitting machine, reducing waste fabric, and increasing customer satisfaction. It consists of three components: Fabric Defect Detection (FDD), Knitting Fabric Management System (KFMS), and Pailung Online Management System (POMS).

Fabric Defect Detection (FDD)

FDD is a system that utilizes cameras, fitted inside the knitting machinery, and equipped with computer vision to detect defects during production. When a defect gets detected, the knitting machine can be shutdown, immediately, pausing production until the problem has been solved, and reducing the manufacturer’s waste fabric losses.

As much as 15% of knitted fabric may go to waste during production, due to defects such as snags and needle lines. This can result in significant financial losses for manufacturers, and negative impacts on the environment. What’s even worse for manufacturers, is when defective fabric reaches the customer, leading to quality complaints that can threaten future business.

It’s all too easy for a human to miss a tiny defect in a long roll of fabric, and for that fabric to be delivered to the customer by mistake. That’s why Pailung has been working hard to develop more advanced ways of detecting fabric defects.

The FDD system is installed close to the top of cylinder, and has the ability to immediately detect any defect. The system can also generate reports on defect types, locations, and frequencies, which can help manufacturers analyze and improve their production processes.

Knitting Fabric Management System (KFMS)

KFMS is a system that stores an archive of knitting detail resources. Every fabric that a Pailung knitting machine produces can be saved in this database, enabling any technician to produce all of those fabrics without prior knowledge of how they’re made.

Whereas, in the past, one technician might have all the know-how for producing a certain fabric, now any technician can produce that fabric. This effectively transfers all fabric production know-how from the individual technician to the factory as a whole.

Detailed parameters can be saved for each fabric:

- Knitting parameters, including machine type, yarn type, specification, yarn length, and weight etc.

- Adjustment parameters, including knitting needle, tension, angle, and timing etc.

The KFMS also allows technicians to create new fabrics by modifying existing ones or combining different ones. The system can also simulate how the fabric will look like before production, saving time and resources.

Pailung Online Management System (POMS)

POMS is a system that allows the technician to control multiple knitting machines from a single computer. All workflows, from production to order scheduling and machine monitoring, can be performed remotely using this central system.

The POMS can also connect with the FDD and KFMS systems, enabling real-time defect detection and correction, as well as easy access to fabric resources. The system can also provide data analysis and visualization on production efficiency, quality control, energy consumption, and maintenance status.

The POMS can also integrate with other systems such as ERP or MES, creating a seamless digital network for textile manufacturing.

Key Insights

- AI Fabric Inspection From Pailung is a software suite that uses computer vision to detect fabric defects inside the knitting machine

- The software suite consists of three components: FDD, KFMS, and POMS

- The software suite aims to reduce waste fabric losses, increase customer satisfaction, transfer know-how from technicians to factories, enable remote control and monitoring of machines, and provide data analysis and visualization

- The software suite is part of Pailung’s efforts to aid textile manufacturers in their digital transformation and enable them to reap the benefits of textile industry 4.0