In recent years, Santoni, a pillar in Italian machinery, teamed up with Groz-Beckert. Their mission? To craft a groundbreaking, self-cleaning knitting system named INNOTAS. This innovation emerged from the Lonati Group, marking a significant stride forward in knitting technology.

Why INNOTAS?

The knitting world faces two critical demands: sustainability and efficiency. Groz-Beckert, driven by these needs, reached out to Santoni. Their goal was clear—develop an energy-efficient solution for today’s market. After thorough research, they embarked on creating a novel self-cleaning mechanism within the knitting machine.

What Makes INNOTAS Special?

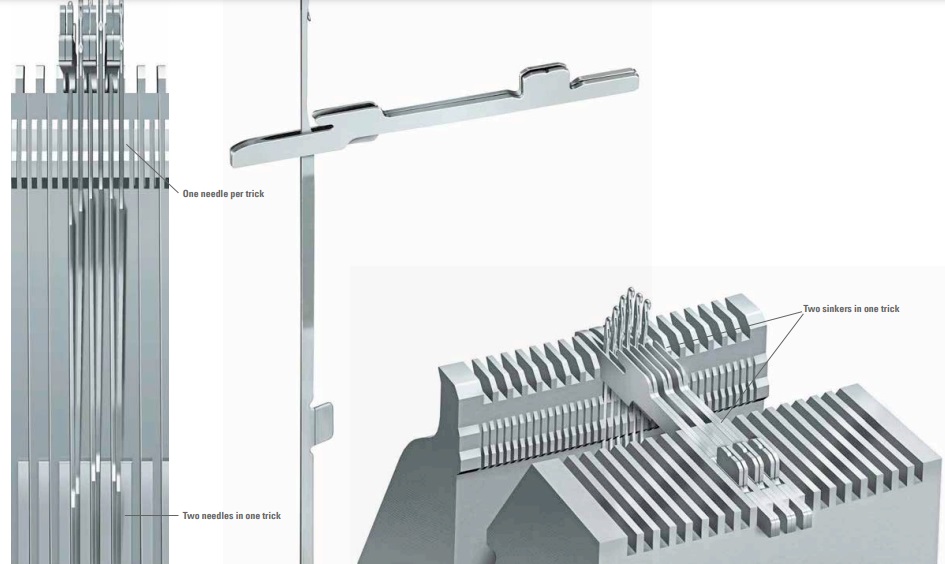

The core of INNOTAS lies in its unique design—the SAN™ DUO needle paired with the SNK DUO-OL sinker. This setup doubles up the elements in both the needle and sinker channels, paving the way for impressive functionality:

- Reduced Soiling: The dual arrangement cuts down lint and dirt accumulation.

- Automatic Lint Removal: The advanced design ensures lint is cleared out automatically, boosting the machine’s efficiency.

- Extended Cleaning Intervals: With less frequent cleaning needs, productivity soars.

The Design Edge

Both the SAN™ DUO needle and the SNK DUO-OL sinker boast a low shank with a unique breaking notch. This design minimizes dirt build-up and enables controlled needle breakage, thus reducing knitting errors and machine downtime.

Collaboration and Innovation

Groz-Beckert does not just create; it collaborates. The firm offers partnership opportunities for machine builders eager to innovate or enhance their products. Their Technology and Development Center (TEZ) provides the perfect setting for these co-development projects. The partnership with Santoni has not only spurred innovation but also led to joint patents, benefiting both entities immensely.

The Impact on You

Why does this matter to you? Whether you’re in the knitting industry or a consumer of knitted goods, the evolution of such technologies impacts efficiency, product quality, and sustainability. The INNOTAS system by Santoni and Groz-Beckert showcases how collaborative innovation can lead to real-world efficiency and environmental gains. This is not just about machines knitting faster; it’s about smarter, cleaner technology shaping the future of textiles.

Looking Ahead

As we advance, the intersection of technology and traditional industries like knitting continues to deepen. Systems like INNOTAS are just the beginning. For businesses, staying ahead means embracing these innovations. For consumers, it translates to higher quality and more sustainable products. This is the future—thread by thread, innovation by innovation.

This exploration of Santoni and Groz-Beckert’s collaboration provides a snapshot of how targeted innovation can redefine industry standards and influence our decisions and practices. The knitting industry is not just about yarn and needles; it’s about pioneering solutions that resonate across global markets.