Desizing is a crucial step in the textile industry that removes the protective coating on the surface of warp yarns in woven fabrics to ensure high efficiency, effectiveness and quality of subsequent stages such as bleaching, scouring, dyeing and printing. However, traditional desizing methods involve the use of large amounts of water and chemicals that have negative impacts on the environment and human health. How can we desize cotton fabric in a more sustainable way that reduces water and energy consumption, as well as chemical waste? One answer may be GRINP Sustainable Desizing Process.

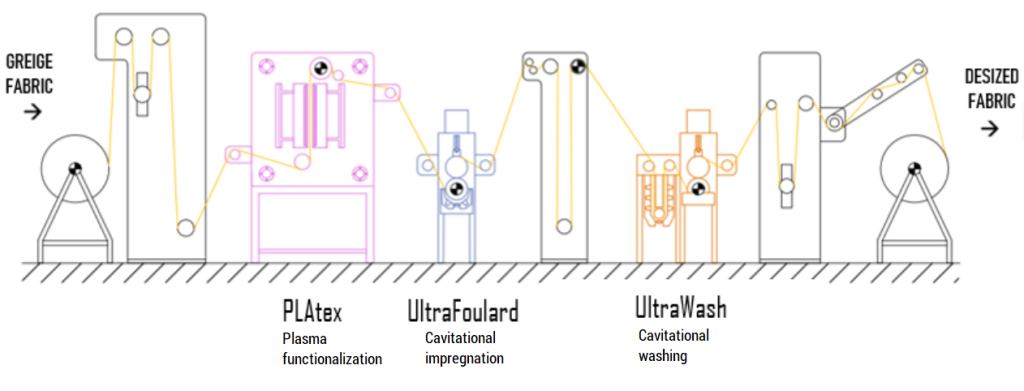

Grinp Sustainable Desizing Process, a novel and innovative method developed by Grinp, a company that specializes in plasma technology for textile finishing. This process uses plasma functionalization, cavitational impregnation, and cavitational washing to desize and purge cotton fabric in a continuous line that saves up to 80% of water and energy compared to traditional methods.

In this article, we will explain how this process works, what are its key characteristics and advantages, and how it can help you achieve your sustainability goals in the textile industry.

Plasma Functionalization

Plasma functionalization is the first step of the Sustainable Grinp Desizing Process. It is a plasma treatment made with Grinp PLAtex plasma machine that allows to functionalize the fabric to make it receptive to the following impregnation.

Plasma is a state of matter that consists of ionized gas molecules that can interact with the surface of materials. By applying plasma to cotton fabric, Grinp PLAtex machine can modify its physical and chemical properties, such as wettability, adhesion, dyeability, and biodegradability.

Plasma functionalization is 100% dry and plays a key role in ensuring the sustainability of the process. It also improves the quality of the fabric by enhancing its softness, smoothness, and brightness.

Cavitational Impregnation

Cavitational impregnation is the second step of the Sustainable Grinp Desizing Process. It represents the impregnation of the fabric in the desizing solution using Grinp UltraFoulard module.

The UltraFoulard module is composed of sonotrodes, which are devices that generate ultrasound waves in liquids. These waves create tiny bubbles that implode violently, creating high pressure and temperature zones. This phenomenon is called cavitation and it allows the deepest impregnation of the fabric, reaching the inner part of the fibre.

Thanks to the proprietary recipe developed by Grinp, the fabric is desized and purged at once. The desizing solution contains enzymes that break down the starch molecules on the surface of the fibre into smaller units that can be easily washed away. The purging solution contains surfactants that remove impurities such as wax, pectin, and mineral salts from the fibre.

Cavitational impregnation is a highly efficient and eco-friendly method that reduces the amount of chemicals needed for desizing and purging. It also improves the quality of the fabric by increasing its absorbency, whiteness, and dyeability.

Cavitational Washing

Cavitational washing is the last step of the Sustainable Grinp Desizing Process. It represents the washing of the fabric in Grinp UltraWashing module.

The UltraWashing module also uses sonotrodes to create cavitation in water. The ultrasound waves stimulate water movement inside the fibre to guarantee full cleaning using a low quantity of water3.

Cavitational washing is a revolutionary and sustainable method that eliminates the need for rotary stocking and hot water. It also improves the quality of the fabric by removing any residual chemicals or impurities from the fibre.

Key Characteristics of Sustainable Grinp Desizing Process

The Sustainable Grinp Desizing Process has many unique features that make it stand out from other desizing methods. Here are some of them:

- The process is innovative and sustainable because it allows to save up to 80% of water and energy

- The process is continuous and does not require any rotary stocking: the result is shorter process time and no room needed for stocking

- Water consumption is extremely low and the washing is included in the process

- There is no need to wash the fabric after Grinp desizing line

- The desizing machine can be equipped with a zero water unit for the complete recycling of water

- The process improves the quality of the fabric by enhancing its softness, smoothness, brightness, absorbency, whiteness, and dyeability

Advantages of Sustainable Grinp Desizing Process

The Sustainable Grinp Desizing Process offers many benefits for the textile industry and the environment. Here are some of them:

- It reduces the environmental impact of desizing by minimizing water and energy consumption, chemical waste, and carbon footprint

- It increases the productivity and efficiency of desizing by reducing process time, space, and costs

- It improves the performance and quality of desizing by ensuring deep impregnation, cleaning, and functionalization of the fabric

- It meets the customer demand for sustainable and high-quality textile products

- It complies with the regulations and standards for environmental protection and human health

Conclusion

The Sustainable Grinp Desizing Process is a game-changer in the textile industry that can help you achieve your sustainability goals while improving your productivity and quality. It is a novel and innovative method that uses plasma technology, cavitational impregnation, and cavitational washing to desize and purge cotton fabric in a continuous line that saves up to 80% of water and energy compared to traditional methods. It also improves the quality of the fabric by enhancing its softness, smoothness, brightness, absorbency, whiteness, and dyeability.

If you are interested in learning more about this process or want to try it for yourself, you can visit Grinp website or contact them directly. They will be happy to assist you and answer any questions you may have.

References

Desizability and Biodegradability of Textile Warp Sizing Materials and Their Mechanism: A Review | SpringerLink :