For most people, the intricate processes behind the textile industry remain out of sight. Yet, this industry claims a significant spot as one of the most hidden and misunderstood sectors. Imagine a simple t-shirt undergoing more than ten processes across different factories on various continents – it’s a complex journey often invisible to the average consumer.

The Shifting Demands of the Textile Industry:

The textile industry is witnessing a radical shift. Major brands, the visible faces of this sector, are intensifying demands on their supply chains. These demands range from capturing fast-changing fashion trends and reducing inventory to save costs, to improving quality and increasing data for regulatory compliance. Amidst these escalating requirements, suppliers are challenged to keep costs unchanged.

The Need for Modern Textile Factories:

This pressure cooker scenario opens opportunities for rethinking how textile factories operate. The status quo is no longer viable for financial growth or reducing environmental impact. A combination of commercial incentives and regulatory pressures is prompting a necessary evolution in the industry. The idea of a ‘Modern Textile Factory’ is emerging as a key player in this transformation.

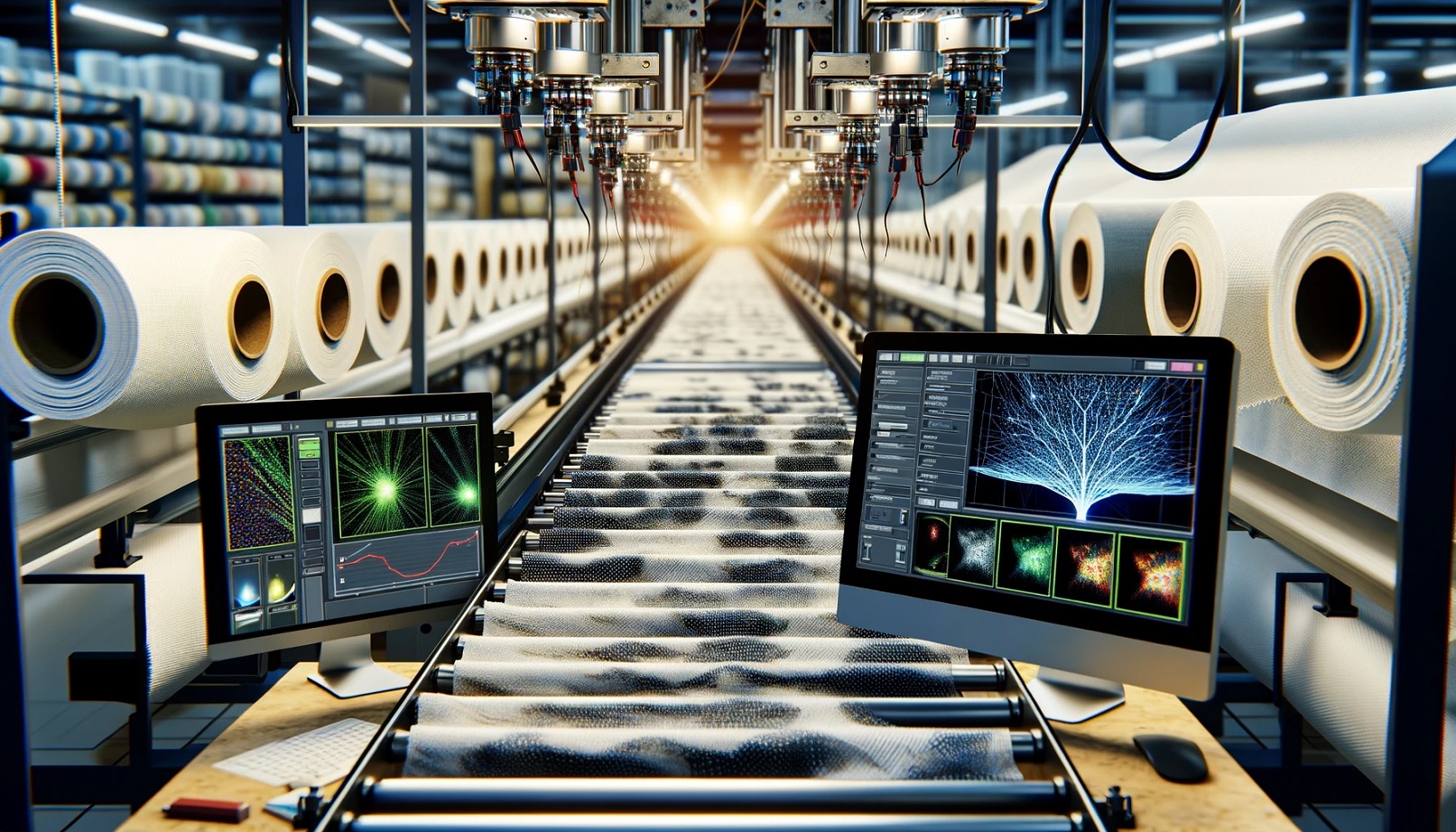

Defining the Modern Textile Factory:

A Modern Textile Factory is not defined by traditional methods like manual data entry or reliance on pen and paper. Instead, it signifies a shift towards automation, digitalization, and transparency. This change is crucial for competitiveness and sustainability, as it allows for improved operations and accountability.

Challenges and Opportunities:

Modernizing textile factories is not a simple task. With tight margins and limited budgets, suppliers need to prioritize their investments wisely. The textile supply chain is under constant pressure from fashion brands for cost-efficiency, making it imperative for factories to adopt a proactive approach.

The Urgency of Modernization:

The term ‘Modern Textile Factory’ is chosen over more futuristic labels like ‘Factory of the Future’ for a reason: the need for modernization is immediate. Delaying this evolution risks obsolescence in an increasingly competitive and environmentally conscious market.

The Sustainability Factor:

Modernizing textile factories is also crucial for sustainability. The majority of a brand’s emissions occur in its supply chain, particularly in clothing production. Without modernized factories, the textile industry’s environmental footprint is unlikely to decrease significantly.

Global Perspectives and Progress:

Thankfully, the journey towards modernization has already begun. From Portugal to Pakistan, Turkey to Bangladesh, leading factories worldwide are taking steps to evolve. However, the pace of this change needs to accelerate to meet the growing demands and environmental challenges.

Conclusion:

Modern Textile Factories stand at the heart of this industry’s transformation. The shift towards these advanced facilities is not just a trend; it’s a necessity for those who wish to remain relevant and successful in a rapidly evolving market. Only those who embrace modernization will flourish in the coming years.

Keywords: Modern Textile Factory, Textile Industry Transformation, Supply Chain Modernization, Sustainability in Textile Industry, Industry 4.0 in Textiles, Environmental Impact of Textile Production, Advanced Manufacturing in Textiles.