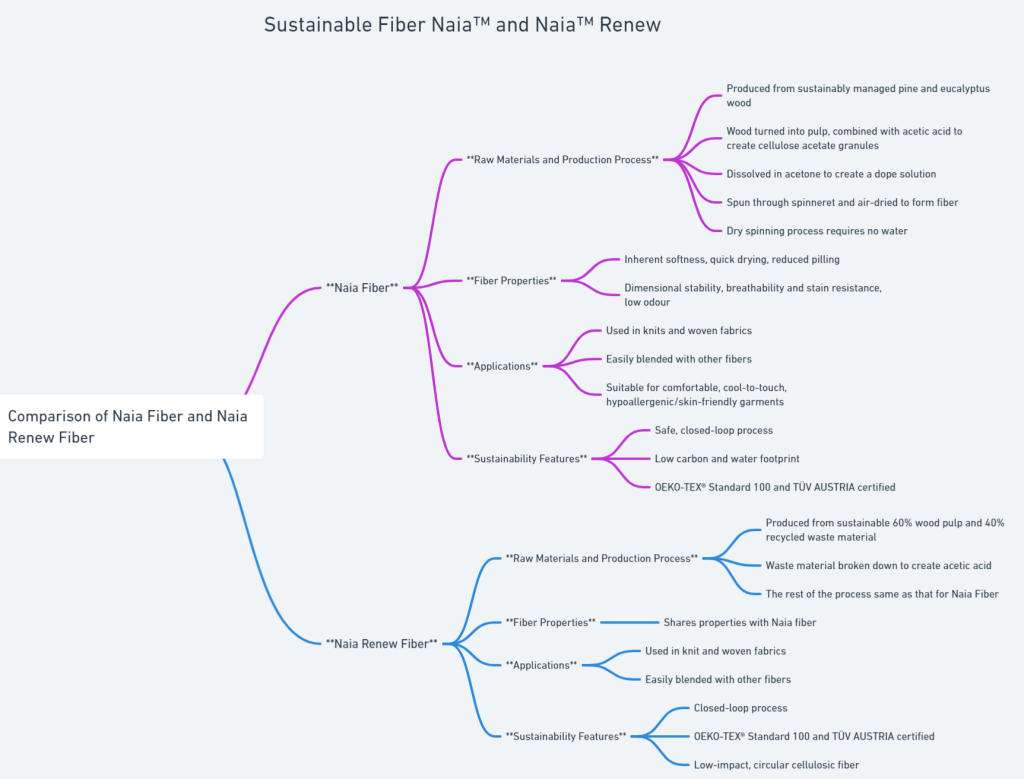

Discover all about sustainable fiber Naia™ and Naia™ Renew: raw materials, production process, properties and applications.

Naia™ Fiber

Raw Materials and Production Process

Naia™ from Eastman is produced from sustainably managed pine and eucalyptus wood sourced from certified forests and plantations in North America and Brazil.

The wood is turned into wood pulp, which is then combined with acetic acid to create cellulose acetate granules.

These granules are dissolved in acetone in a closed-loop process to create a cellulose acetate dope solution.

The solution is then spun through tiny holes in a spinneret and air-dried to form cellulose acetate fiber. This dry spinning process does not require any water

Fiber Properties

Naia fiber is known for its inherent softness, quick drying properties, and reduced pilling.

It also offers good breathability and dimensional stability, with garments maintaining their shape even after washing.

Naia fiber is also resistant to tough stains like coffee and red wine, and it effectively halves sweat odor compared to polyester.

Applications

Naia fiber can be used in knits and woven fabrics and can be easily blended with other fibers.

It is suitable for creating garments that are comfortable, with good drape, cool to touch, and hypoallergenic/skin-friendly.

Sustainability Features

Naia fiber is produced in a safe, closed-loop process where solvents are recycled back into the system for reuse.

It has a low tree-to-fiber carbon and water footprint, and it is favorably ranked on the Higg Materials Sustainability Index.

Naia fiber is OEKO-TEX® Standard 100 Product Class I certified and has been certified as biodegradable and compostable by TÜV AUSTRIA.

Naia™ Renew Fiber

Raw Materials and Production Process

Naia Renew fiber is produced from a combination of 60% sustainable wood pulp and 40% certified recycled waste material.

The waste material is broken down into basic building blocks and used as feedstock to create acetic acid. This process diverts hard-to-recycle waste material from landfills.

The rest of the production process is similar to that of Naia fiber, involving the creation of cellulose acetate granules, a dope solution, and finally the fiber itself. .

Fiber Properties

Naia Renew fiber shares many of the same properties as Naia fiber, including inherent softness, quick drying, and reduced pilling. .

Applications

Naia Renew fiber can also be used in knit and woven fabrics and can be easily blended with other fibers. .

Sustainability Features

Naia Renew fiber is produced in a closed-loop process, with solvents recycled back into the system for reuse.

It is OEKO-TEX® Standard 100 Product Class I certified and has been certified as biodegradable and compostable by TÜV AUSTRIA.

The use of recycled waste material in its production makes Naia Renew a low-impact, circular cellulosic fiber.