Learn how Artistic Denim Mills (ADM), a leading denim manufacturer, is creating sustainable denim that is good for people and the planet

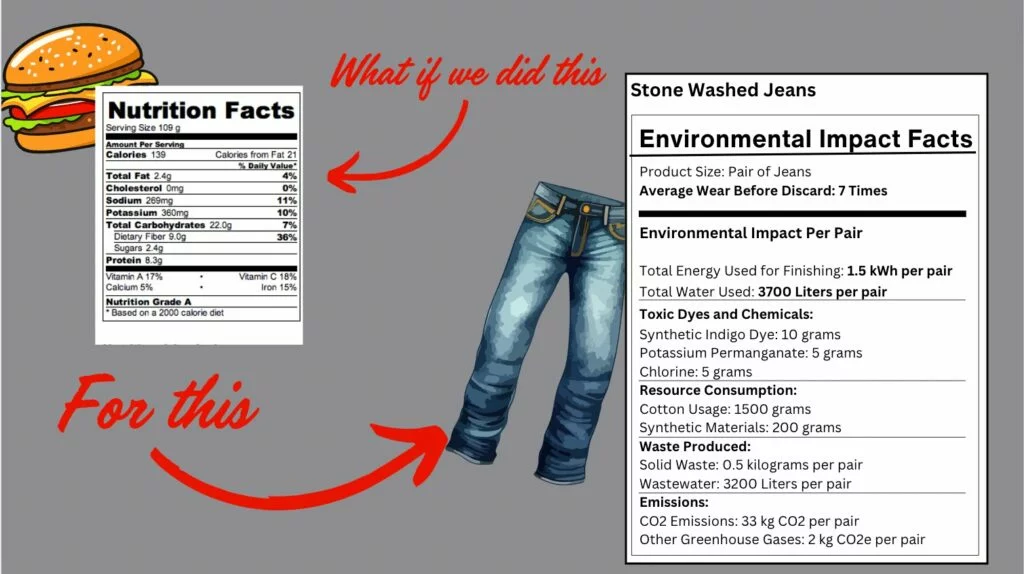

Denim is one of the most popular fabrics in the world, but it also has a dark side. The production of denim consumes a lot of water, energy and chemicals, and generates a lot of waste and pollution.

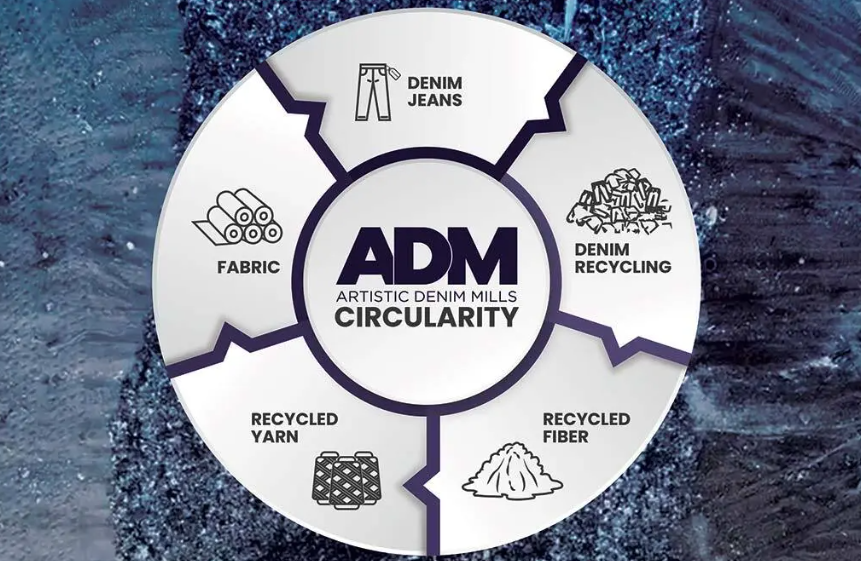

But what if there was a way to make denim more sustainable, without compromising on quality, comfort or style? That’s the vision of Artistic Denim Mills (ADM), a leading denim manufacturer based in Pakistan. ADM is committed to creating denim that is good for people and the planet, using innovative technologies, products and initiatives that reduce its environmental impact and enhance its social responsibility.

In this article, we will explore how ADM is advancing the sustainable future of denim, by focusing on three key aspects: raw materials, processes and products.

Raw Materials

One of the first steps to make denim more sustainable is to use raw materials that are ethically sourced and have a lower environmental footprint. ADM partners with globally recognized brands and manufacturers to create sustainable fabrics that meet a wide variety of demands, such as the comfortable and sculpting properties of four-way stretch.

Some of the raw materials that ADM uses include:

- Organic cotton: Cotton that is grown without the use of synthetic pesticides, fertilizers or genetically modified seeds. Organic cotton reduces water consumption by up to 91 percent, and greenhouse gas emissions by up to 46 percent, compared to conventional cotton1.

- Recycled cotton: Cotton that is made from pre- or post-consumer textile waste, such as discarded garments or fabric scraps. Recycled cotton reduces the need for virgin cotton, and saves water, energy and landfill space.

- Recycled polyester: Polyester that is made from recycled plastic bottles or other plastic waste. Recycled polyester reduces the dependence on petroleum, and prevents plastic from ending up in oceans or landfills.

- Tencel™: A branded lyocell fiber that is made from wood pulp sourced from sustainably managed forests. Tencel™ is biodegradable and compostable, and uses a closed-loop process that recovers and reuses 99 percent of the solvents used in its production.

- Refibra™: A branded lyocell fiber that is made from a blend of wood pulp and recycled cotton scraps. Refibra™ combines the benefits of Tencel™ with the circularity of recycled cotton, creating a new generation of sustainable fibers.

Processes

Another way to make denim more sustainable is to use processes that are more efficient and less harmful to the environment and human health. ADM employs state-of-the-art technologies and techniques that reduce its chemical usage, water consumption and carbon emissions.

Some of the processes that ADM uses include:

- Liquid indigo dyeing: A dyeing method that uses liquid indigo instead of powder indigo, which has less sulfide content than traditional dyes. Liquid indigo dyeing reduces chemical usage by 70 percent, compared to conventional denim factories.

- Aniline-free indigo dyeing: A dyeing method that uses indigo that is free of aniline, a toxic substance that can cause skin irritation, respiratory problems and cancer. Aniline-free indigo dyeing eliminates the risk of aniline exposure for workers and consumers, and prevents aniline from being discharged into waterways.

- Laser finishing: A finishing method that uses computerized lasers to create fading patterns on denim, instead of using harmful chemicals or labor-intensive hand sanders. Laser finishing reduces chemical usage by 90 percent, water usage by 50 percent, and energy usage by 30 percent.

- E-flow technology: A technology that uses air to create nano-bubbles that transfer chemicals onto fabrics in a more efficient way. E-flow technology reduces water usage by up to 95 percent, chemical usage by up to 50 percent, and energy usage by up to 79 percent.

- Ozone technology: A technology that uses ozone gas to bleach fabrics without using chlorine or other bleaching agents. Ozone technology reduces water usage by up to 50 percent, chemical usage by up to 80 percent, and energy usage by up to 28 percent.

All of the chemicals that ADM uses are OEKO-TEX certified and comply with the Zero Discharge of Hazardous Chemicals (ZDHC) Foundation Roadmap set by a coalition of fashion brands, value chain affiliates, and industry, NGO and government associates for safer production processes.

Products

The final step to make denim more sustainable is to create products that are durable, functional and fashionable, and that meet the needs and expectations of consumers. ADM offers a range of products that cater to different markets and segments, such as:

- HYPERFLEX: A denim fabric that features ROICA™ Eco-Smart technology, which is a recycled elastane that offers a four-way stretch that adapts to the body’s movements, while reducing environmental impact. HYPERFLEX is suitable for active wear, sportswear and casual wear.

- ECOCHIC: A denim fabric that features Tencel™ x Refibra™ technology, which is a blend of lyocell fibers made from wood pulp and recycled cotton scraps. ECOCHIC is biodegradable and compostable, and offers a soft hand feel, a natural look and a high performance. ECOCHIC is suitable for eco-conscious consumers who value quality and style.

Conclusion

Artistic Denim Mills (ADM) is a leading denim manufacturer that is committed to making denim more sustainable, through its innovative technologies, products and initiatives. By using ethical raw materials, efficient processes and functional products, ADM is creating denim that is good for people and the planet.