Saurer’s Sustainable Textile Technology

Textile Industry Facing Challenges

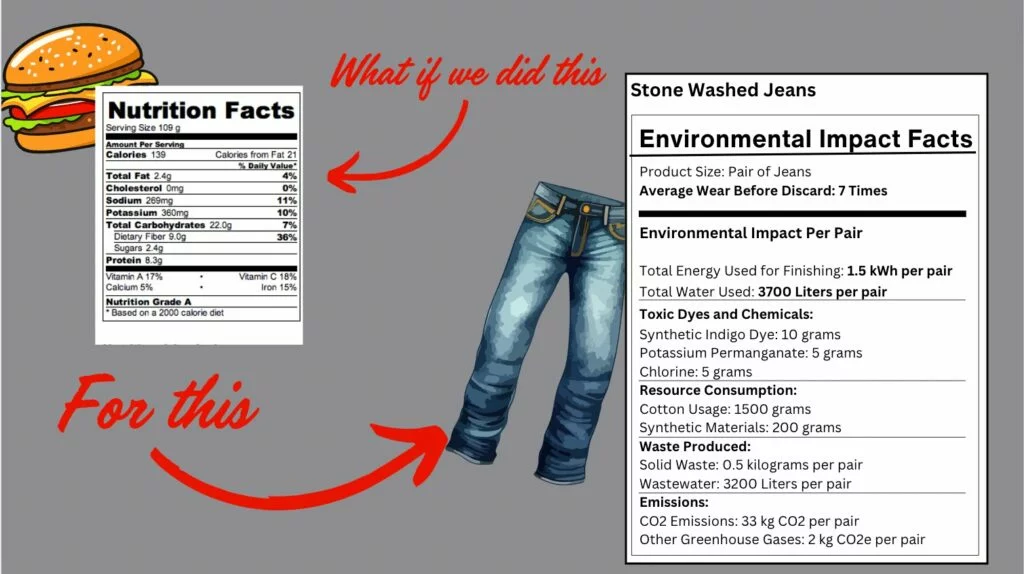

The textile industry is grappling with challenges around sustainability, energy efficiency, and adapting to market trends. With growing demand for recycled materials, high-quality yarn, and automated processes, manufacturers struggle to balance productivity, cost-effectiveness, and environmental concerns.

The Difficulty of Finding Efficient Solutions

Manufacturers are challenged with meeting consumer demands for higher quality and sustainability while reducing costs and energy use. Managing these issues with conventional methods is increasingly difficult. The need for advanced, automated machinery that can streamline production while maintaining quality has never been greater.

Saurer Unveils Cutting-Edge Technology at IGATEX

Saurer is addressing these challenges with a suite of innovative technologies presented at IGATEX in Lahore.

1. Autoairo: Revolutionizing Air-Spinning

- Belairo Yarn: Offers unparalleled absorbency, texture, and durability, ideal for towels and polo shirts.

- Autonomous Spinning: Individual spinning positions maximize productivity and minimize pilling, even after extensive washing.

2. Autocoro 11: Leading Recycling Technology

- Recycling Xtreme: The Autocoro 11’s seamless spinning reduces yarn breaks with Synchropiecing 60 technology.

- Energy Efficiency: Uses 10% less energy than its predecessor, significantly reducing operational costs.

3. BD Series: Semi-Automatic Rotor-Spinning

- BD 8: Sets new standards in efficiency and energy use with DigiJSI technology, making it competitive globally.

- Flexibility and Efficiency: Fast startup, high doffing speed, and customizable functions help customers adapt to market demands.

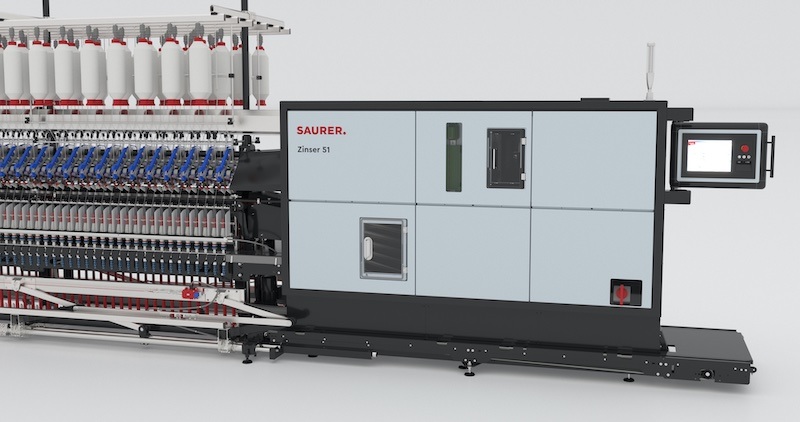

4. Zinser 51 and ZI 72XL: Ring-Spinning Innovation

- High Tolerance: Optimized for processing recycled fibers, with high tolerance for short fibers.

- Automation: Can produce different yarn types while enhancing productivity through extended spindle counts.

5. Autocard SC7: Excellence in Spinning Preparation

- Advanced Carding: Delivers increased production and improved quality through digitalization, automation, and ergonomic features.

6. Automation Solutions

- Bobbin Transport System: Efficiently links roving frames with ring frames.

- Future Innovations: Automated Guided Vehicles (AGVs) and piecing robots offer customizable automation solutions.

7. SUN – Service Unlimited

- Energy Efficiency: Retrofit kits and upgrades reduce the energy consumption of existing machinery.

- Sustainability Focus: Helps extend machine life while integrating new, energy-efficient features.

8. Texparts Components

- Advanced Parts: High-quality drafting arms, long-lasting rings, and energy-saving Eshape spindles improve spinning quality while reducing energy use.

Conclusion

Saurer’s comprehensive technology at IGATEX demonstrates a commitment to helping manufacturers meet market challenges. Their focus on sustainable, high-quality yarn production and advanced automation is reshaping how textile companies can thrive in today’s competitive, environmentally-conscious market.