Discover Syre’s innovative textile-to-textile recycling technology for post-consumer polyester textile waste

The textile industry is grappling with a significant challenge: reducing its environmental impact while maintaining product quality. Traditional polyester production is heavily reliant on crude oil, contributing to high carbon emissions and resource depletion.

Unsustainable Practices in Textile Production

The current textile industry faces two primary issues: environmental degradation and resource inefficiency. Virgin polyester, derived from crude oil, emits significant CO2 and depletes non-renewable resources. Even bottle-to-fiber recycled polyester (rPET) presents challenges, as it diverts PET bottles from their optimal recycling path, disrupting a potentially circular system.

The Consequences of Ignoring the Problem

Ignoring these issues perpetuates a cycle of waste and inefficiency. The production of virgin polyester continues to emit high levels of CO2, exacerbating climate change. Moreover, relying on bottle-to-fiber rPET compromises both the quality of recycled textiles and the integrity of PET recycling systems. This linear model leads to increased waste and environmental harm, making it imperative to seek more sustainable alternatives.

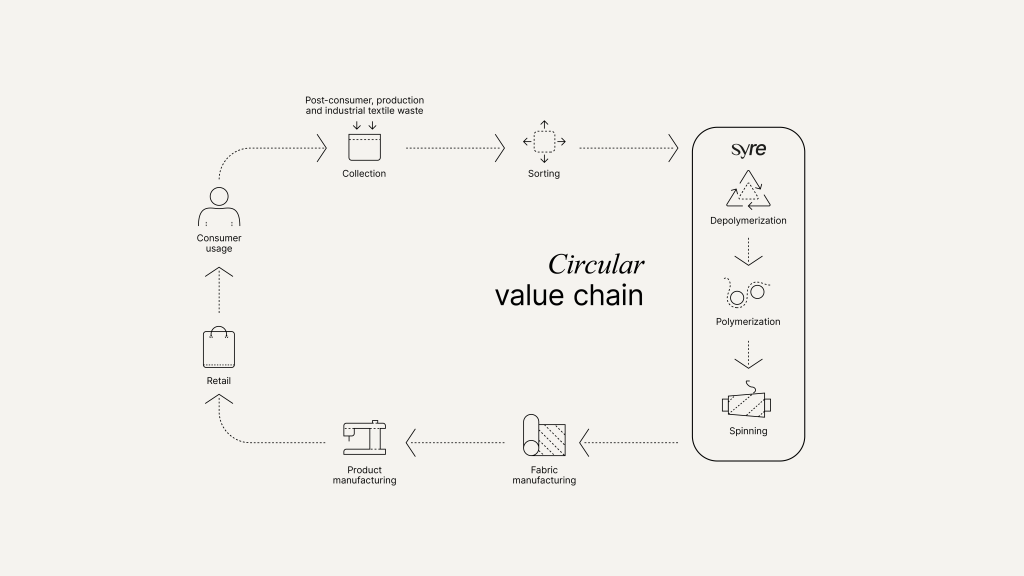

Syre’s Circular Textile-to-Textile Recycling

Syre introduces a revolutionary textile-to-textile recycling system, creating a truly circular economy. This method allows polyester fibers to be recycled repeatedly without quality loss, outperforming both virgin polyester and bottle-to-fiber rPET in sustainability and performance.

Superior Sustainability

Syre’s process reduces CO2 emissions by up to 85% compared to traditional oil-based polyester production. By recycling textiles back into textiles, Syre minimizes resource extraction and waste, significantly lowering the industry’s carbon footprint.

High Quality

The recycled polyester produced by Syre matches the quality of virgin polyester, ensuring durability and performance. This high-quality output surpasses that of rPET, which often falls short in maintaining fiber strength and longevity.

Plug-and-Play Integration

Syre’s solution is designed for easy integration into existing textile value chains. Companies can adopt this technology without incurring significant switching costs, facilitating a smooth transition to more sustainable practices.

Regional Value Chains and Industry Collaboration

Syre is committed to building vertically integrated value chains in various regions, ensuring that textile waste is efficiently converted into high-quality recycled polyester locally. This regional approach reduces transportation emissions and supports local economies.

Collaboration is key to Syre’s strategy. The company actively partners with industries such as apparel, automotive, and home interiors to close the loop on textile waste. By working together, these industries can drive the shift from a linear to a circular economy, creating a more sustainable future.

Conclusion

Syre’s innovative textile-to-textile recycling technology offers a comprehensive solution to the pressing environmental challenges faced by the textile industry. By reducing carbon emissions, maintaining high product quality, and enabling easy integration into existing systems, Syre paves the way for a sustainable and efficient textile economy. As industries adopt this circular approach, they not only mitigate their environmental impact but also contribute to a more resilient and sustainable global economy. Embracing Syre’s solution is a crucial step towards a greener future for textiles.