NeoLast™ fibers, born from the innovative partnership of Celanese and leading sports brands, are set to transform the world of performance stretch fabrics. Unlike traditional elastane, NeoLast™ fibers offer a greener, more durable option for athletes and environmentally conscious consumers alike.

Understanding NeoLast Fibers:

NeoLast fibers are made using Celanese’s unique solvent-free melt-extrusion process. This method eliminates the use of potentially hazardous chemicals typically found in spandex production, making NeoLast an environmentally friendlier choice. These fibers are designed to be more durable and longer-lasting. They create desirable opportunities for reuse and reducing the need for frequent replacements.

Sustainability Features:

- Solvent-Free Production: The innovative process for NeoLast™ fibers sidesteps the harmful chemicals common in elastane production. This marks a significant step towards environmental friendliness.

- Recycling Potential: NeoLast™ fibers can be a key player in addressing the challenge of recycling blended fabrics.

- Longer-Lasting Garments: The durability of NeoLast™ fibers means less waste and more sustainable consumption. The clothes last longer and maintain their integrity over time.

Differences from Traditional Elastane:

- Manufacturing Process: NeoLast™ fibers are produced using a proprietary melt-extrusion process, as opposed to the chemically-intensive methods used for elastane. NEOLAST™ fiber is made from thermoplastic elastoester polymers, it can help to address the challenge of recycling blended fabrics.

- Environmental Impact: The solvent-free production of NeoLast™ is more eco-friendly than traditional elastane manufacturing.

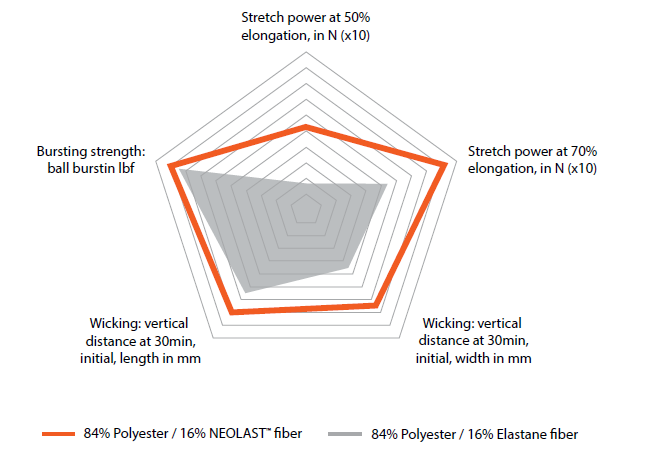

- Durability and Longevity: NeoLast™ fibers offer enhanced stretch, moisture management, and overall durability, outperforming conventional elastane in terms of longevity and performance.

Applications in Sportswear:

From sports apparel and outdoor wear to swimwear and medical compression gear, NeoLast™ fibers provide a wide range of applications. These fibers can be knitted or woven into stretch fabrics, offering a blend of 2-40% NeoLast™ to meet various performance specifications.

Conclusion:

NeoLast™ fibers represent a significant leap forward in both performance and sustainability. By choosing sportswear made with NeoLast™, you’re not just elevating your game; you’re also supporting a more sustainable future.