Plastic waste is a global crisis. Every year, millions of tons of PET (polyester), a common type of plastic, accumulate in landfills and oceans. Traditional recycling methods are not enough. They cannot handle all types of PET waste, especially colored and multi-layered plastics. The situation is worsening. PET production relies heavily on oil, contributing to pollution and resource depletion. Many PET items end up as waste after a single use. This is unsustainable. We need a better solution.

A Groundbreaking Solution

CARBIOS introduces a groundbreaking response. Their first commercial plant in Longlaville, France, uses enzymatic depolymerization technology. This innovative method breaks down PET waste into its basic components. These can be remade into new PET products. This is a real shift towards a circular economy.

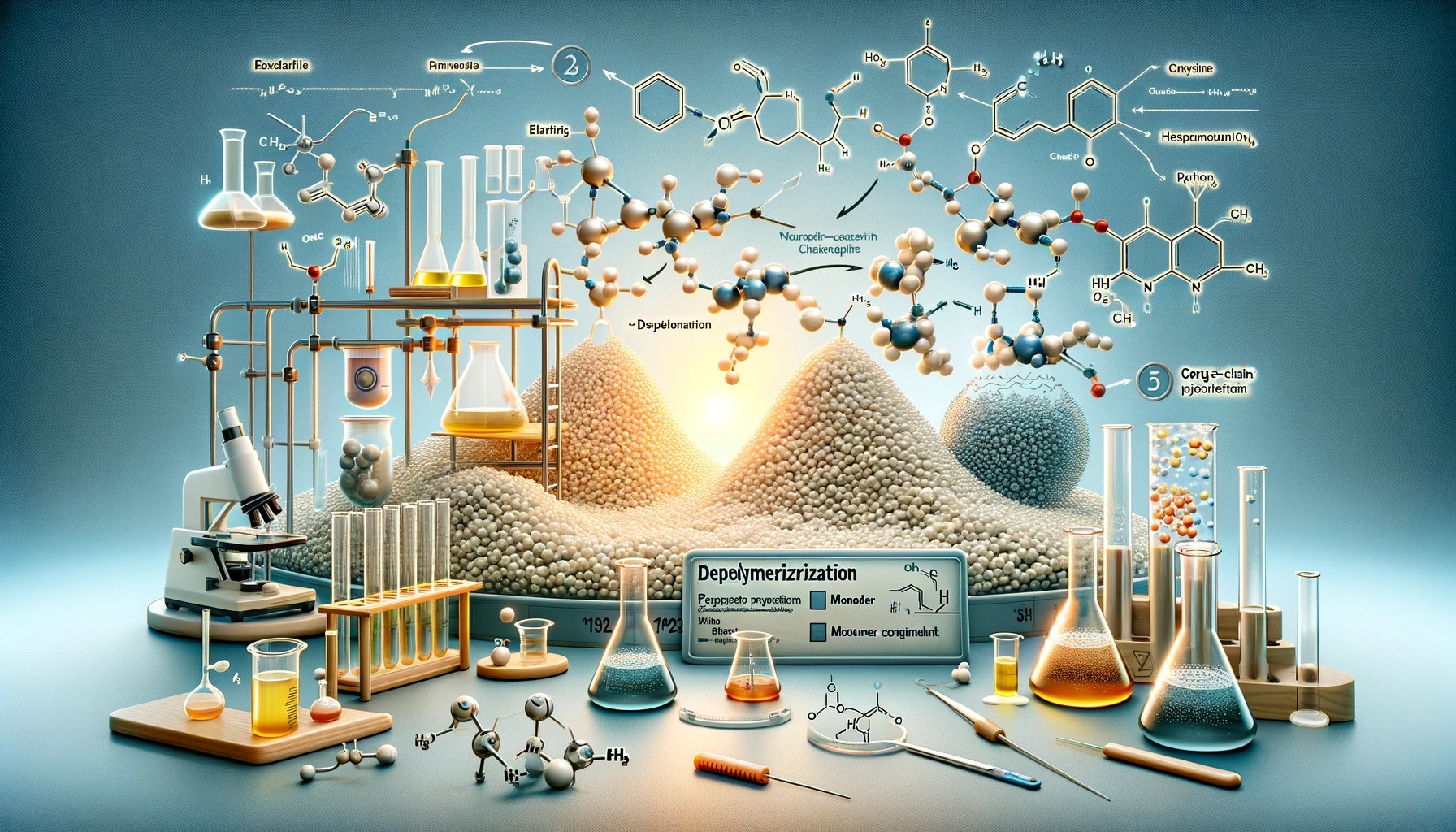

Inside CARBIOS’ Technology

CARBIOS’ technology transforms PET waste into valuable resources. This enzymatic process is efficient and eco-friendly. It handles types of PET previously deemed unrecyclable. This includes colored plastics and textiles. The Longlaville plant will process 50,000 tons of PET waste yearly. This is equivalent to 2 billion colored bottles, 2.5 billion food trays or 300 million T-shirts.

The Impact and Future

This plant is more than a technical achievement. It is a step towards sustainable industrial practices. It creates jobs and sets environmental benchmarks. The plant will also bolster France’s role as a leader in green technology.

CARBIOS collaborates with major brands and receives significant support from French authorities. This includes a substantial grant as part of the France 2030 initiative. These partnerships are vital for scaling up this technology.

Conclusion

CARBIOS’ enzymatic recycling plant represents a significant advancement in tackling plastic pollution. It aligns with global efforts to reduce waste and recycle more efficiently. This plant is not just about recycling. It is about rethinking how we manage resources for a sustainable future.

The launch of this facility is a promising step towards a world where plastic never becomes waste. It is a beacon of innovation, sustainability, and hope for the environment. As we move forward, supporting technologies like this will be crucial in shaping a greener planet.