A new, fast and inexpensive process for the 100% recycling of carbon-fibre composites has been developed at the University of Colorado, along with a method for turning the recycled resins and fabrics into a new material that is just as effective as the original product – but cheaper to produce.

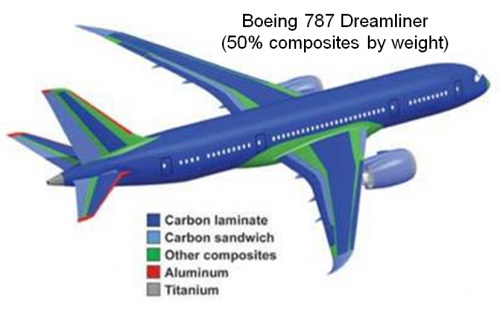

This has major implications for a rapidly-accelerating industry. The use of carbon-fibre composites in Airbus and Boeing passenger planes has increased from 10% to 50% in the past ten years, and now the same is poised to happen in commercial cars. This will potentially create a major issue when it comes to recycling in the future.

Lower-performing nonwovens for various automotive and aerospace applications have so far been the only products to be made from recycled carbon fibres.

Now, Wei Zhang, CU-Boulder associate professor of chemistry and biochemistry and his team have developed a method for reclaiming all of the carbon fibre and the resin simply by soaking the composite in an organic solution at room temperature.

“The resin that holds the composite together can be chemically broken down and separated from the fibres, enabling both to be re-used to make more composite materials of the same strength,” says Philip Taynton, who along with Zhang and CU-Boulder alumnus Chris Kaffer have also founded a start-up company working to bring the process and new composites to market. “Other than mild stirring, no extra energy is used in the recycling process and no waste is created by the recycling process. It is a closed-loop energy efficient cradle-to-cradle recycling solution.”

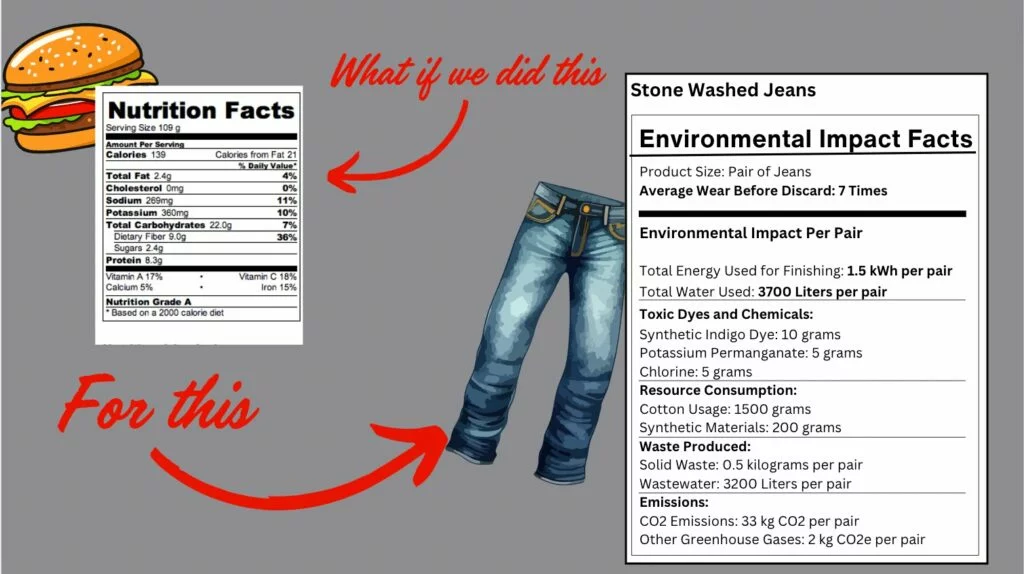

Currently it’s common for as much as 50% of composite materials to be discarded as scrap during the manufacturing process.

Adrian Wilson: International Technical Textiles Journalist