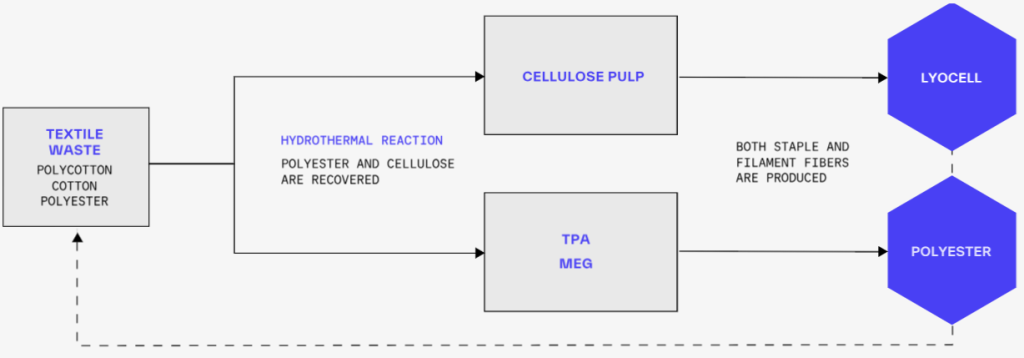

Here is all about Circ ® Lyocell and Circ ® Polyester produced from recycled polyester/cotton blended waste:

Circ ® Lyocell:

Raw Material:

Circ’s lyocell is regenerated cellulose made from cotton separated from recycled polyester/cotton blended waste. It’s a sustainable alternative to traditional tree-based lyocell.

Process:

Firstly, cotton and polyester are separated from polyester/cotton blend waste using a hydrothermal process. Then, from the cellulose pulp generated from reclaimed cotton, a closed-loop production method is employed to create staple or filament lyocell fibers.

Properties:

Circ’s lyocell is drop-in ready, meaning it can seamlessly replace conventional virgin lyocell in fabric production. It’s properties match (or exceed) the quality of virgin, tree-based lyocell.

Applications:

Circ lyocell can be used for a wide range of textile applications, including clothing, home textiles, and more.

Sustainability:

By utilizing textile waste, Circ contributes to a circular economy and reduces the environmental impact of fashion.

Circ ® Polyester:

Raw Material:

Circ’s polyester is derived from recycled cotton-polyester textile blends, after separating polyester from cotton using a hydrothermal process.

Process:

Circ’s hydrothermal process separates the polyester from cotton out of polyester/cotton blend waste. The reclaimed polyester intermediates are then used to regenerate recycled polyester.

Properties: The regenerated polyester looks, feels, and performs just like virgin polyester.

Applications:

Circ polyester can be incorporated into clothing, accessories, and other textile products, just like virgin polyester.

Sustainability:

Circ’s dual output approach allows for the recycling of blended textiles, contributing to a more sustainable fashion industry.